Recent Posts

- Vinovation: Exploring the Coolest Techniques in Modern Winemaking

- Wine Spotlight: A South African Symphony – Pinotage Elegance

- Wine Spotlight: Bold Elegance – South African Shiraz Unveiled

- Spring is Almost Here! Chilean Grapes & Juices + South African Juices Available For Purchase

- Spring Into Winemaking: Discover Musto Wine Grape Co.’s Spring Offerings

Archives

- June 2025

- March 2025

- February 2025

- November 2024

- September 2024

- August 2024

- April 2024

- March 2024

- January 2024

- December 2023

- November 2023

- October 2023

- September 2023

- August 2023

- July 2023

- June 2023

- May 2023

- April 2023

- March 2023

- February 2023

- September 2022

- August 2022

- April 2022

- March 2022

- December 2021

- November 2021

- October 2021

- September 2021

- August 2021

- July 2021

- June 2021

- May 2021

- April 2021

- March 2021

- February 2021

- October 2020

- September 2020

- August 2020

- July 2020

- June 2020

- May 2020

- April 2020

- March 2020

- February 2020

- January 2020

- December 2019

- November 2019

- October 2019

- September 2019

- August 2019

- July 2019

- April 2019

- March 2019

- February 2019

- January 2019

- December 2018

- November 2018

- October 2018

- September 2018

- August 2018

- July 2018

- June 2018

- May 2018

- April 2018

- March 2018

- February 2018

- January 2018

- November 2017

- October 2017

- September 2017

- August 2017

- July 2017

- June 2017

- May 2017

- April 2017

- March 2017

- February 2017

- January 2017

- December 2016

- November 2016

- October 2016

- September 2016

- August 2016

- July 2016

- June 2016

- May 2016

- April 2016

- March 2016

- February 2016

- January 2016

- September 2015

- August 2015

- April 2015

- February 2015

- January 2015

- December 2014

- November 2014

- September 2014

- July 2014

- June 2014

- March 2014

- June 2013

- July 2012

Categories

barrel

Wine Barrel Care and Maintenance

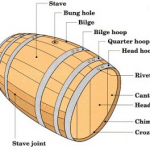

Winemaking is an investment in most winemakers’ eyes. One of your most tedious but worthwhile investments will be a wine barrel. They are expensive to produce and challenging to maintain, but the impact it can have on the quality of your wine makes it worthwhile. This article will cover the anatomy of the barrel, how to clean it, and the maintenance you should familiarize yourself with if you plan on owning one.

Inspecting your barrel

The first thing you should do as soon as you receive your new (or used) wine barrel is to inspect it. You should start by visually examining the barrel’s exterior. Keep an eye out for broken chimes, dented or displaced heads, and misaligned staves. Also look for scrapes, gouges, and any torn or burred hoops. Next, you’ll need to inspect the inside of the barrel. The inside should be completely dry and free of mold. The area where the head meets the staves can be a breeding ground for mold, which usually occurs from a combination of standing water and exposure to starch used in the construction of the barrel. Lastly, observe the aroma of the barrel. The barrel should smell clean, fresh, oaky, and/or toasty. Other than sulfur, there should be no chemical odors and certainly no aroma of spoilage.

Prepping your barrel for wine

This will include one last inspection of your barrel, which is testing your barrel for leakage first. You need to rehydrate your barrel, or “swell” it to prepare it for wine, but it’ll kill two birds with one stone allowing you to inspect for any possible leaks. There are two ways to swell your barrel, the first option being the hot water/quick soak method. The second option is a coldwater/high volume soak. The only main difference is the speed of which the soaking gets done.

Hot water/quick soaking consists of filling the barrel with 3-5 gallons of filtered, chlorine-free, hot water. The ideal temperature for this would be about 180 degrees Fahrenheit. Use caution when using water hotter than this, or using high-temperature steam as this can degrade and damage the barrel. Once you’ve filled your barrel, place your stopper in the bunghole. Rotate the barrel from side to side, completely wetting the barrel’s interior. Stand the barrel upright on its side (one head facing down, the other up) and let stand for about 4 hours to rehydrate the head. Repeat with the opposite side for an additional 4 hours. During these processes, make sure to continuously check for any leakage. If there are no leaks, turn the barrel so it’s bunghole is facing toward and allow to drain and dry completely.

Coldwater/high volume soaking calls for filling he barreling completely with filtered, chlorine-free, cold water. Once you’ve filled the barrel completely, place your stopper in the bunghole and let the barrel stand for about 24 and 48 hours. Once no leaks are present, empty the barrel and allow it to drain and dry completely.

If your barrel continues to leak after multiple swelling attempts

If after either of these methods are complete the barrels still exhibit leaks, repeat the swelling process as it’s possible it just needed more time to swell. There are some additional methods of swelling you can attempt that are more aggressive but can possibly help seal any leaks.

The submerging method:

We have found that sometimes soaking the interior and exterior of the barrel simultaneously can help to get it swelled. Start by placing the barrel upright on one head in a large container. Fermentation tubs work great for this. Next, fill the barrel halfway until water is seeping from the bunghole, then fill the container it’s in up to the same bunghole. Let the barrel sit overnight, then remove all water from the barrel and container, flip the barrel onto its other head and repeat the process. Once emptied, use the cold water method and check for any leaks.

The hoop tightening method:

The hoops on a barrel can become loose when it becomes dry. Using a hoop driver, or if no hoop driver is available, a cold chisel to hammer the hoops toward the center of the barrel. Workaround the barrel, hammering firmly at around one-quarter increments of the circumference. It may be necessary to remove the hoop nails to allow the hoop to slide tighter onto the barrel.

The Barrel Sealing Wax method:

Beeswax can be used to seal small leaks. The first step is to mark any leaks with a pencil or chalk. To properly apply sealing wax, first make sure the barrel is dry. Next, gently sand leaking areas with rough sandpaper. Knead a small piece of beeswax in your hand and work the wax into the area using a putty knife. Beeswax will not change the flavor of your wine and is completely safe to use.

After several attempts, if your barrel continues to leak, it is important to call your sales rep immediately. Empty the barrel, allow it to drain, and completely dry. Next, you have to treat each barrel with 10-20 grams of sulfur sticks (or the equivalent gas form) and re-insert the stopper. This will ensure that you are still maintaining the integrity of the interior of the barrel.

Storing your barrels

Ideally, barrels should always have wine in them. If you are in between winemaking projects though, or you’re waiting for harvest, there are a few guidelines you should follow when storing your barrels. If you are storing a new barrel, store in a cool, humid environment. Some new barrels arrive with their plastic film still on them – if yours does, keep that film on if you plan to store them for a significant amount of time. The process of storing a used barrel requires a bit more work.

If you are ready to empty your barrel, empty it and wash the barrel out with hot water until all of the deposits and tartaric crystals have been dissolved and emptied. Repeat if necessary. If you have access to larger volumes of hot water, fill the barrel completely and let sit overnight. Once emptied, rinse the barrel with cold water and let it dry with the bunghole facing down. Allow to completely dry, and then burn sulfur sticks or discs in the barrel and place stopper in the bunghole. This burning treatment should be repeated every six weeks or so until you are ready to use the barrel again. Finally, store your barrels in a cool, humid environment.

Other tips and tricks for maintaining your barrel

Never leave water in a barrel for more than two days. If the swelling process takes longer, empty, and refill the barrel with fresh water to avoid mold and spoilage micro-organism growth.

A full barrel is a happy barrel! If possible, try to refill your barrel immediately after it has been emptied and cleaned. This way you will never have to re-swell it and there is much less opportunity for bacteria and other spoilage organisms to get into the barrel.

Never use chlorine in or around a barrel, or any winemaking equipment for that matter. TCA, also known as cork taint, can infect much more than just corks. A barrel is a vulnerable place for TCA to be absorbed into due to the spores, molds, and natural phenolics of the wood.

When in doubt, throw it out – or repurpose your barrel for something other than winemaking. If you suspect that there are spoilage organisms in your barrel even after you have tried ozone/steam/proxycarb, (you can find info on these here) err on the side of caution and retire it. You can ruin any future wine you put into such a barrel and it can possibly infect the rest of your winemaking equipment if they are stored near them. Barrels can be repurposed into planters, furniture, and more!

Where can I purchase wine barrels?

Musto Wine Grape Company carries a few categories of wine barrels including new and used American and French wine barrels! Email sales@juicegrape.com or call (877) 812 – 1137 to speak with one of our Musto Crush Crew members to get your order placed, or if you need any assistance in using, maintaining, or storing your barrel. We also offer ozoning treatments if you are dealing with a problem barrel. We are here to provide everything you need to make the wine of your dreams, including the customer support to ensure your success!

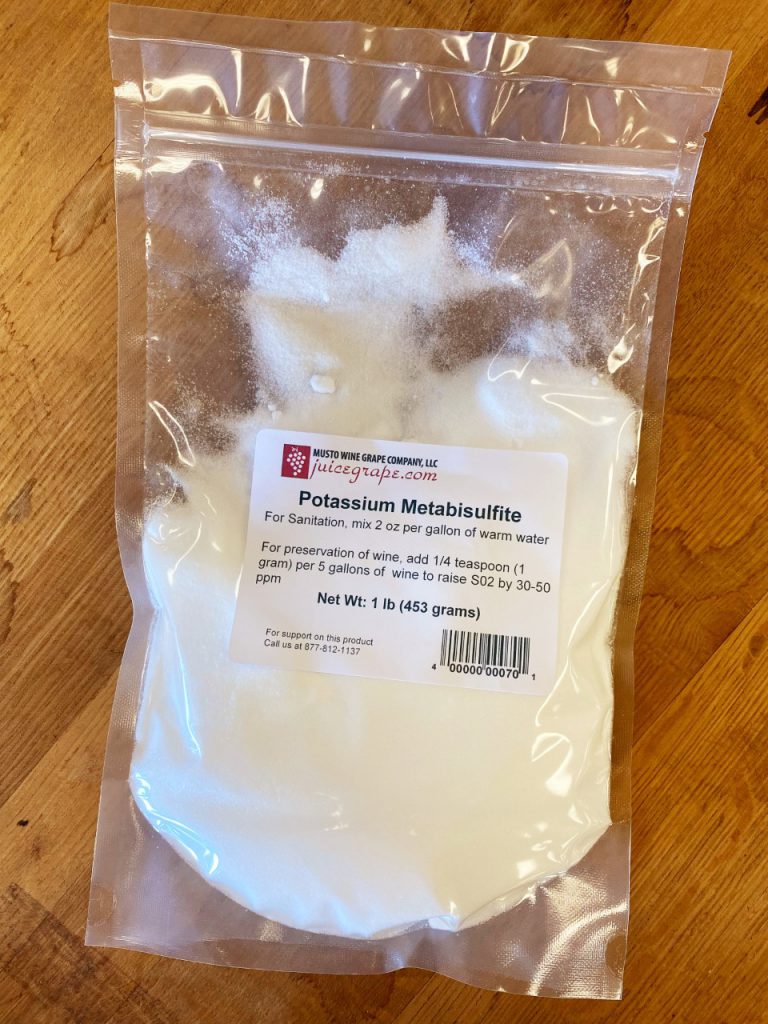

Potassium Metabisulfite: Product Spotlight

What is Potassium Metabisulfite?

Potassium Metabisulfite is an antioxidant and sanitizer, and has several uses in winemaking. After crushing and de-stemming, it is used to help kill off any spoilage bacteria and natural yeast that may be present on the grapes or equipment. It also helps to preserve wine, specifically protecting it against oxidization.

Throughout the entire winemaking process, it’s important to measure your SO2 levels and adjust as needed to improve and lengthen the preservation of your wine. The exact amount needed to be effective is entirely determined by the pH of the wine. Also, free SO2 levels fall faster in a wooden barrel versus in glass or stainless steel tanks, so make sure you manage your SO2 levels very closely.

How do I use it?

If you are adding Potassium Metabisulfite to your must, the proper amount is ¼ teaspoon per 5 gallons of must. If you are making an SO2 sanitizing solution, add 8 teaspoons for every 1 gallon of water. Place into a spray bottle for quick and easy use. After cleaning your equipment and again before use, spray the solution generously and shake off/let any extra solution drip dry.

Potassium Metabisulfite has a shelf life of about one year if you are using it to add to your wine. If you have some that is over a year old, no worries! It still functions as a sanitizer, just make sure you separate and label each to avoid any mix ups.

Where can I get it?

You can find and purchase Potassium Metabisulfite here. Need assistance in using SO2, whether adding to your wine or sanitizing your equipment? Give us a call at (877) 812 – 1137 to speak with a sales associate who can help you!

Follow us on Instagram here and like us on Facebook here. For Virtual Winemaking Classes click here.

Archives

- June 2025

- March 2025

- February 2025

- November 2024

- September 2024

- August 2024

- April 2024

- March 2024

- January 2024

- December 2023

- November 2023

- October 2023

- September 2023

- August 2023

- July 2023

- June 2023

- May 2023

- April 2023

- March 2023

- February 2023

- September 2022

- August 2022

- April 2022

- March 2022

- December 2021

- November 2021

- October 2021

- September 2021

- August 2021

- July 2021

- June 2021

- May 2021

- April 2021

- March 2021

- February 2021

- October 2020

- September 2020

- August 2020

- July 2020

- June 2020

- May 2020

- April 2020

- March 2020

- February 2020

- January 2020

- December 2019

- November 2019

- October 2019

- September 2019

- August 2019

- July 2019

- April 2019

- March 2019

- February 2019

- January 2019

- December 2018

- November 2018

- October 2018

- September 2018

- August 2018

- July 2018

- June 2018

- May 2018

- April 2018

- March 2018

- February 2018

- January 2018

- November 2017

- October 2017

- September 2017

- August 2017

- July 2017

- June 2017

- May 2017

- April 2017

- March 2017

- February 2017

- January 2017

- December 2016

- November 2016

- October 2016

- September 2016

- August 2016

- July 2016

- June 2016

- May 2016

- April 2016

- March 2016

- February 2016

- January 2016

- September 2015

- August 2015

- April 2015

- February 2015

- January 2015

- December 2014

- November 2014

- September 2014

- July 2014

- June 2014

- March 2014

- June 2013

- July 2012

Recent Comments