SOS: Sluggish/stuck fermentation

Many a winemaker has lamented the dreaded stuck fermentation. With so much to deal with during harvest time, the last thing you should be worried about is a ferment that has just up and quit. But sometimes it happens – knowing what to do when it does will be a life saver during an otherwise potentially unfortunate moment in a wine’s life. We’re here to walk you through how to handle this, what to do, and most importantly, how to do it.

Step 1: Think about why it may have gotten stuck

This is going to help you moving forward, both with this wine and with future ferments. Was there too much sugar in the juice or must to begin with? Was the fermentation temperature too cool or too hot? Did you choose a yeast that doesn’t do well with high sugar levels? Were nutrient levels too low?

Considerations before restarting

- Adding lysozyme can halt spoilage organisms which are often present in sluggish or stuck fermentations

- Resuke can lower toxin levels that have accumulated which will give you a better chance for a healthy restart. If you add this you will rack off of it 1-2 days later.

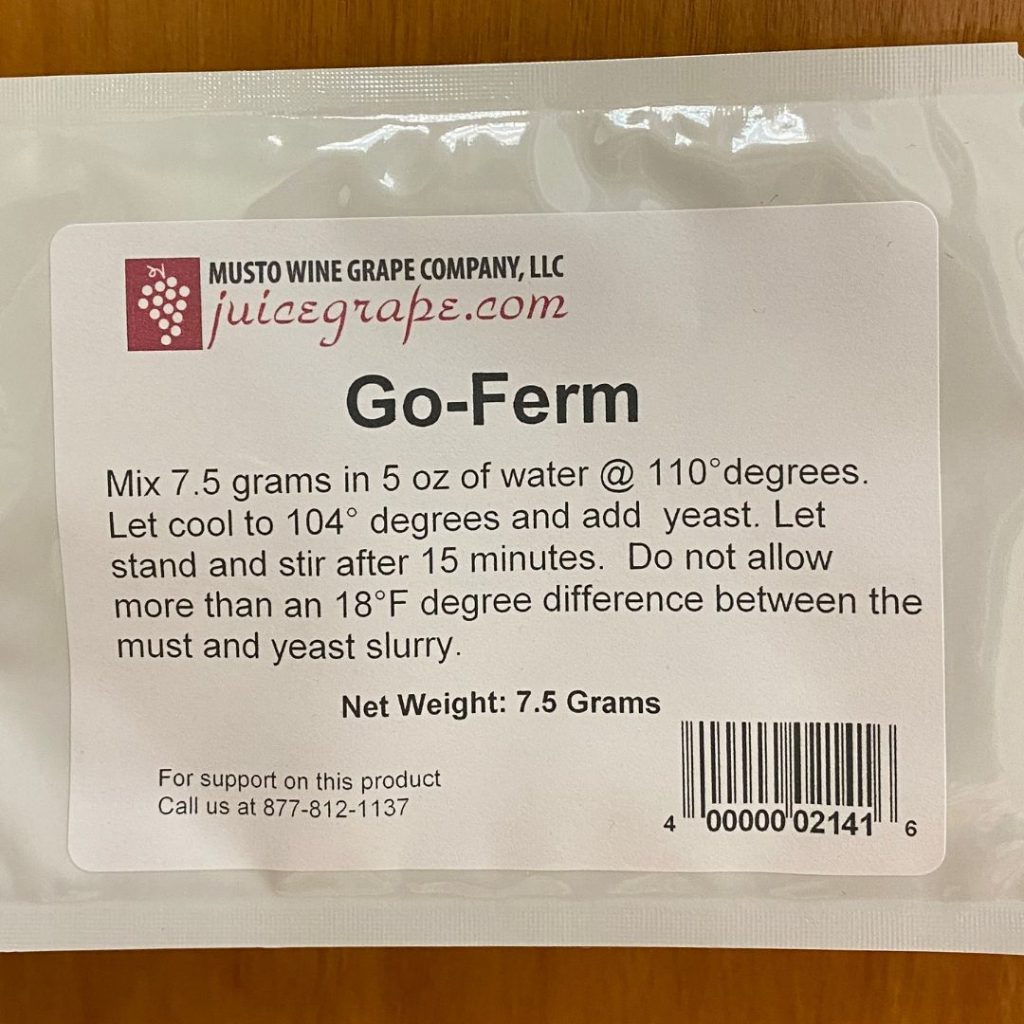

- Incorporate Go-Ferm and Go-Ferm Protect Evolution to ensure health of ensuing restarting fermentation

- Carefully choose what yeast you will re-pitch with. 43, 43 Restart, Fermivin Champion, K1 (V1116), Vin 13, BC, and DV10 are great choices.

Step 2. Add a complex yeast nutrient

This is going directly into the stuck wine tank. If you think you may have a spoilage bacteria problem, this is the time you would be adding lysozyme.

Step 3. Combine equal parts stuck wine and water in another vessel

This is known as the “mother restart tank.” At this moment it will be totaling 2% of whole volume.

Step 4. Rehydrate yeast nutrient + yeast as you would when pitching yeast the first time

This is the exact same process you did during the initial yeast pitch.

Step 5. Add the yeast to the mother restart tank

As always, there should be a <18F difference between the yeast mixture and the mother restart tank liquid temperature.

Step 6. Add 10% of the stuck wine to the starter culture

Wait 20-30 minutes.

Step 7. Add 20% of the stuck wine to the starter culture

Wait 20-30 minutes.

Step 8. Repeat until the remainder of the stuck wine has been added to the mother restart tank

Don’t skimp on waiting the 20-30 minutes at each of the following steps. Give it time to acclimate!

The Winemaker’s Think Tank: Vol 2 – What do I need to get started making wine with fresh juice?

The Winemaker’s Think Tank?

Every Thursday we will post about a few frequently asked questions that our winemaker has answered. If you have a winemaking question you would like to have answered, please email us at support@juicegrape.com and we will try to get into next week’s post. Cheers! 🙂

What do I need to get started making wine with fresh juice?

When elevating your winemaking to the next level, often sourcing the best ingredients is the most direct path to better results. After getting great base experience using wine kits, the next logical step to wine making greatness is fresh juice. When making this change from wine kits to fresh juice, other ingredients may be needed to ensure the juice will reach its greatest potential as wine. First, evaluate your juice for acid (pH) and sugar (Brix). What are the levels present in your juice? If the Brix level is below 20, you may consider adding sugar to increase the Brix levels to 24-26. What is the pH of the wine? Juice should have a pH greater than 3.1 to ensure a successful fermentation. If the pH is higher than 3.8, consider adding tartaric acid. This will ensure a better tasting wine after fermentation as well as a more stable wine.

The next area to consider is yeast. Certain strains of yeast will amplify certain traits within the finished product of wine such as fruit character, spice notes, or floral notes. The yeast has certain parameters that it will ferment best within, so consult a winemaking expert at Musto Wine Grape to help you select the best yeast strain for your wine. The yeast is the important catalyst that will process the grape juice into wine. The yeast will need certain nutrients to best assist it with its fermentation such as a rehydration nutrient like Go Ferm, and subsequent nutrients to finish out the fermentation process such as Fermaid O and Fermaid K. Musto Wine Grape stocks yeast along with all of the aforementioned nutrients in small packages, designed for the individual buckets of juice. This will give you perfectly measured amounts of products to add to your wine, making proper fermentation simple and with no wasted/unused product.

We hope this information helps with your winemaking. If you have any follow up questions or winemaking questions in general, please email us at support@juicegrape.com.

Recent Comments