Wine Spotlight: Bold Elegance – South African Shiraz Unveiled

Interested in making South African Shiraz? Give us a call at 877-812-1137 to speak to a winemaking representative about your order.

Appearance:

In the glass, South African Shiraz commands attention with its deep, inky purple color. The richness of its hue hints at the robust character that awaits.

Aroma:

Upon the first swirl, the nose is greeted by an enticing bouquet of dark fruits and subtle spices. Blackberry and ripe plum take center stage, accompanied by a hint of black pepper and a touch of smoky oak (either French or American oak, medium toast). The aromatic profile is bold and inviting, setting the stage for the complex layers to unfold. (yeast suggestions: BDX, D80, D254)

Palate:

As the wine graces the palate, it delivers a symphony of flavors that reflect the warmth and intensity of the South African sun. Black cherry and blueberry dance alongside notes of dark chocolate and a subtle hint of vanilla from careful oak aging (either French or American oak, medium toast). The wine’s full-bodied nature is complemented by velvety tannins that add a luxurious texture, creating a well-balanced and deeply satisfying experience.

Flavor Profile:

South African Shiraz is a showcase of the varietal’s bold and expressive character. The dark fruit flavors are complemented by a savory undercurrent, with a touch of black pepper adding a hint of spice. The integration of oak is seamless, contributing to the wine’s complexity without overpowering its vibrant fruit profile.

Pairing Suggestions:

A robust Shiraz is a natural companion to hearty dishes. Pair it with a juicy grilled steak, lamb stew, or a rich, meaty pasta for a perfect match. Its bold flavors and well-structured tannins also make it an excellent candidate for aging, allowing the wine to evolve and develop further complexity over time.

Overall:

South African Shiraz is a testament to the region’s ability to produce wines of depth and character. It balances power with finesse, showcasing the winemaker’s artistry in capturing the essence of the grape and the terroir. It’s a wine that invites contemplation and celebration.

Interested in making South African Shiraz? Give us a call at 877-812-1137 to speak to a winemaking representative about your order. Cheers!

Hurry! Get Your Spring Orders In Before It’s Too Late!

Dear Valued Winemakers,

We hope this post finds you well and excited about the fantastic Spring products we have in store for you! As we gear up for another exciting week, we wanted to remind you that time is ticking, and we don’t want you to miss out on the opportunity to get your hands on our amazing Spring offerings.

From South Africa:

Juice Varieties: Shiraz, Merlot, Pinotage, Cabernet Sauvignon, Semillon, Chardonnay, Pinot Grigio, Chenin Blanc, Sauvignon Blanc

Fresco Juice Varieties: Cabernet Sauvignon, Pinotage, Shiraz, Sauvignon Blanc

Arrivals: Last week in April

From Chile:

Grapes Varieties: Carmenere, Cabernet Sauvignon, Cabernet Franc, Malbec, Merlot, Petite Verdot, Pinot Noir, Syrah, Chardonnay, Pinot Grigio, Sauvignon Blanc, and Viognier

Juice Varieties: Carmenere, Cabernet Sauvignon, Cabernet Franc, Cabernet/Merlot Blend, Malbec, Merlot, Petite Verdot, Pinot Noir, Syrah, Chardonnay, Pinot Grigio, Sauvignon Blanc, and Viognier.

Fresco Juice Varieties: Cabernet Sauvignon, Carmenere, Malbec, Merlot, Chardonnay, Chardonnay-Semillon, Sauvignon Blanc, Viognier

Arrivals: First week in May

Whether you’re looking for that perfect blending wine, treating yourself to something special, or simply stocking up on your favorite variety, now is the time to act! Our boats will be arriving soon and they are brimming with top-quality products waiting to be discovered. We wouldn’t want you to miss out on the fun of Spring winemaking. Don’t let procrastination steal your joy – place your order today and let the anticipation begin!

So, what are you waiting for? Join the excitement, and let’s make this Spring winemaking experience one to remember!

Thank you for choosing Musto Wine Grape Co. We truly appreciate your continued support.

Happy Winemaking!

Warmest Regards,

The Musto Crush Crew

877-812-1137

Wine Spotlight: Amorosso/Amarone Blend

One of our all time favorite Italian wine juices will be arriving in October, the Amorrosso/Amarone Blend. Sweet and bold, this wine is popular at any table. It will be arriving in early October from Italy. The Amarone fresh juice is available for pre-order and on demand pick up. The Amorosso Fresco is pre-order only. Please call 877-812-1137 to put in your order. We have a huge list of Italian wine juices for sale. Be sure to give us a call to check out what is available.

The Blend:

Amorosso/Amarone wine is a unique and highly regarded red wine produced in the Valpolicella region of Veneto, Italy. It is known for its rich, full-bodied flavor, high alcohol content, and complex aroma. Primarily made from three grape varieties: Corvina, Corvinone, and Rondinella. The grapes are carefully selected from well-maintained vineyards, and only the ripest bunches are chosen for this blend.

Appassimento:

The key step in Amarone production is the drying process, also known as “appassimento.” Instead of pressing the grapes immediately, they are spread out on wooden racks or straw mats in well-ventilated rooms, lofts, or drying chambers. During this time, they lose water content, which concentrates their sugars, flavors, and aromas. This process can reduce the weight of the grapes by 30-40%.

After the drying process, the grapes are gently crushed to release their juice. The grape skins are thick and full of flavor due to the drying process.

Winemaking Notes:

Typically, after fermentation, Amorossa/Amarone wine is aged for an extended period in oak barrels. The aging process can range from two to several years, depending on the producer’s preferences. This aging helps mellow the wine’s tannins, integrate its flavors, and develop its complex bouquet. For step by step instructions check out this blog post.

Flavor Profile:

Amorosso/Amarone wine is characterized by its deep ruby-red color, intense and complex aromas of dried fruits, dark cherries, spices, and a full-bodied, velvety texture. It is often enjoyed as a fine wine on its own or paired with hearty dishes like roasted meats, game, and aged cheeses. Due to its unique production method, Amorosso/Amarone tends to be more expensive than many other Italian wines but is highly regarded by wine enthusiasts for its exceptional quality and flavor profile.

Viva Italia!

To make an Italian wine juice order please contact us via sales@juicegrape.com or call us at 877-812-1137, follow us on Facebook, Instagram, and Youtube, or check out the Harvest Tracker and Winemaker Blog on our website- juicegrape.com.

What is the difference between Fresco Juices and Fresh Juices?

What is the difference between Fresco Juice vs. Fresh Juice?

Fresco Juices:

Ever bake a cake from a box and it came out delicious? Did you know you could do the same with winemaking?

Mondiale Fresco is proud to be the only product to offer home winemakers their own vineyard in one unique package. Each pail of juice is pre-balanced and adjusted to ensure you have the best winemaking success possible. Just warm up the juice to fermentation temperature and watch it go.

What does “pre-balanced” and “adjusted” mean?

Every season Mother Nature gives us a different wine grape harvest. Some years the acid, pH, and sugars are all in line with each other. Most times they aren’t and there needs to be some slight adjustments made pre-fermentation to ensure top wine quality. The Fresco juices are adjusted so that the acid, pH, and sugar levels are all in balance with each other. This makes for an easier fermentation and, a very pleasing wine.

Depending on the varietal of wine you choose, enzymes and tannins might be added – all pre-measured, and ready-to-go, just open the packet and add to the pail. These add-ons help with wine clarity and mouthfeel, contributing to the “taste like made from scratch”, or in this case, as if fermented on the skins. The Fresco juices are the best juices to work with for busy winemakers. You get the juice warmed up, watch it ferment, age, and bottle.

Fresh Juices:

Fresh Juices come straight from the press!

Our fresh juices are from the grapes that are crushed, destemmed, and pressed right into the pails. For white wine, this is as if you were crushing and pressing yourself. For red wine the grapes are run through a heat or “hot” press in order to extract the color. Once these pails come up to temperature they can kick off because of the native yeast from the original grapes, or you can kill the native yeast and pitch your own yeast to ensure a more successful fermentation. Either way you are working with the fresh juice, not from concetrate. A delicous wine can be on your table as soon as Christmas!

So what is the difference?

The Fresh Juices are the straight from the press. The Fresco juices are straigth from the press, but pre-balanced and have a few additions made to them to make fermentation easier on the winemaker.

Either way you have delicious wine in the making!

To make an order please contact us via sales@juicegrape.com or call us at 877-812-1137, follow us on Facebook, Instagram, and Youtube, or check out the Harvest Tracker and Winemaker Blog on our website- juicegrape.com.

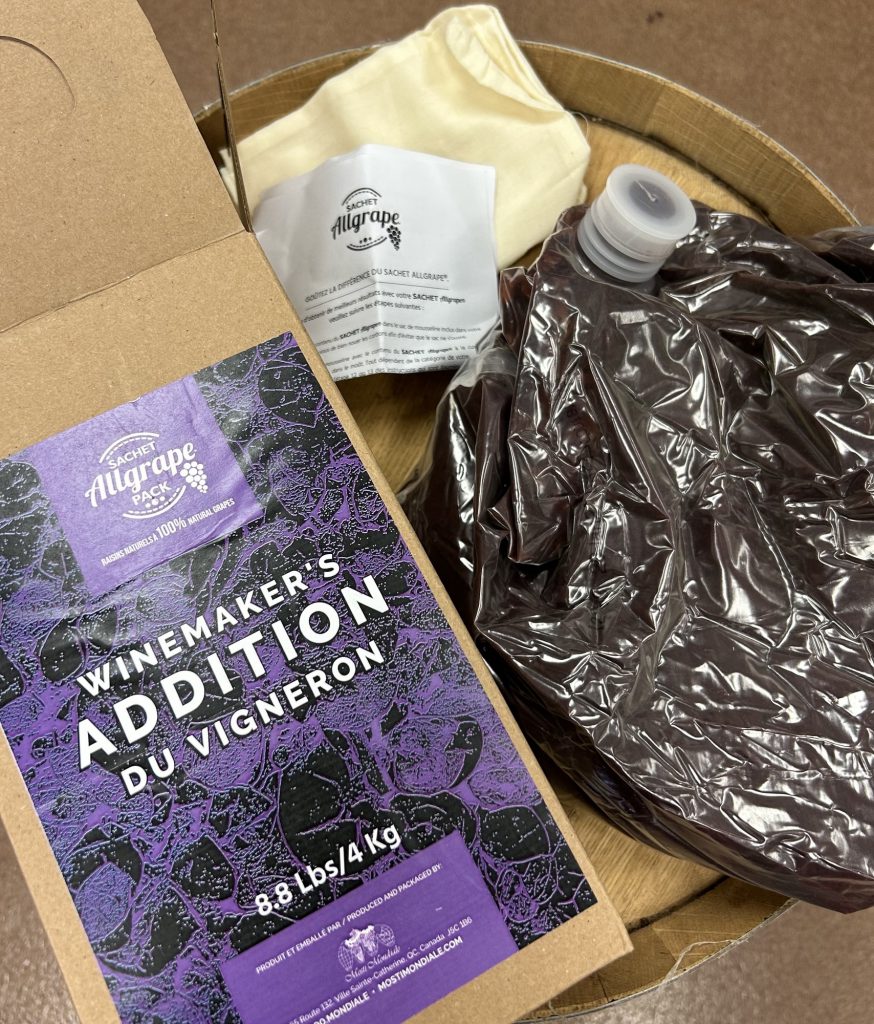

Upgrade Your Winemaking Juice with the AllGrape Pack!

Upgrade Your Winemaking Juice with the AllGrape Pack!

Making from Fresh Juice or Wine Kits produces a fantastic wine, but can sometimes be lacking in tannins, color, flavor, and mouthfeel. This isn’t the winemaker’s fault, this is becasue these types of product do not get ample time on the grape skins to give the wine that extra kick of complexity.

Lucky for you, We Have a Solution! Enter the AllGrape Pack

The AllGrape pack® contains 100% grapes, NO Fillers, NO sweeteners just 100% pasteurized crushed and destemmed grapes as “Mother Nature” intended!

Packed in a sterile, shelf-stable, bag in a box…taste the real Allgrape® difference.

Add it to your Fresh Wine Juice or Wine Kit and see a significant increase in the Flavor Profile, Tanninic Structure, and Mouthfeel in your Juice Wine!

It tastes as if you made wine from grapes!

Sam & Christina did an experiment with Chilean Merlot this Spring. We did one pail with the AllGrape pack and one pail without it. We couldn’t believe the difference! We believe in the product so much so that we discounted it so it’s easier to test out for yourselves. You won’t be disapointed. But hurry because this sale will only last until Novemeber!

FALL SPECIAL!

$33.00 – NOW $25.00

To make a wine juice order or if you have any questions about the AllGrape pack please contact us via sales@juicegrape.com or call us at 877-812-1137, follow us on Facebook, Instagram, and Youtube, or check out the Harvest Tracker and Winemaker Blog on our website- juicegrape.com.

The Italians are Coming!!

There are several compelling reasons to consider

making Italian wine from Musto’s Italian juices.

Variety:

Italy is one of the world’s largest wine producers, and it boasts an incredible variety of wine styles, grape varieties, and regions. Whether you prefer red, white, sparkling, or dessert wines, Italy offers an extensive range to explore.

Terroir:

Italy’s diverse geography, climate, and soils contribute to a rich tapestry of terroirs. Each wine region has its own unique characteristics, producing wines with distinct flavors and profiles.

Food Pairing:

Italian wines are known for their versatility and ability to complement a wide range of cuisines. Whether you’re enjoying pizza, pasta, seafood, or fine Italian cuisine, there’s an Italian wine that pairs beautifully with it.

Quality:

Italy has a long history of winemaking, and many Italian wineries are dedicated to producing high-quality wines. Italy has a significant number of prestigious wine regions and producers, including those in Tuscany, Piedmont, Puglia, and Veneto.

Heritage:

Italy has a deep cultural and historical connection to winemaking. This heritage is reflected in the traditions, techniques, and dedication of Italian winemakers.

Uniqueness:

Italy is home to several unique and iconic wine styles, such as Barolo, Amarone, Chianti, Prosecco, and Brunello di Montalcino, among others. Exploring these wines can be a delightful and enriching experience.

Whether you’re looking for a bold red wine like Barolo, a crisp white like Pinot Grigio, Italy has something to offer for every palate and occasion!

Musto Wine Grape will be receiving Italian wine juices this October! See below for a full list of what is available from Italy this fall.

Musto Wine Grape Italian Juice Offerings:

Fresh Italian Juices:

Amarone

Barolo

Brunello

Chianti

Dolchetto

Lambrusco

Montelpulciano

Moscato

Nebbiolo

Nero D’Avola

Pinot Grigio

Sangiovese

Trebbiano

Valpolicella

Italian Fresco Juices (pre-order only):

Amorosso (Amarone)

Granbarile (Barolo)

Castel del Papa

Il Toscano (Chianti)

Lambrusco

Merlot

Montelpulciano

Nebbiolo

Primitivo

Sangiovese

Pinot Grigio

Trebbiano

To make an order please contact us via sales@juicegrape.com or call us at 877-812-1137, follow us on Facebook, Instagram, and Youtube, or check out the Harvest Tracker and Winemaker Blog on our website- juicegrape.com.

Wine Spotlight: Lanza-Musto Vineyards Malbec

Lanza-Musto Suisun Valley Malbec is a wine that brings velvety sweetness and dark complexity to the table.

Suisun Valley, located in Solano County, California, is not traditionally known for Malbec wine production like some other regions, but it does have a small and growing reputation for producing high quality Malbec wines. If you’re considering buying Suisun Valley Malbec grapes, here are some reasons to consider:

Unique Terroir:

Suisun Valley’s terroir, characterized by its climate, soil, and topography, offers a unique and distinct environment for grape cultivation. While it may not have the recognition of regions like Argentina (known for Malbec), this uniqueness can result in wines with a different expression of the Malbec grape.

Varietal Exploration:

If you enjoy exploring different expressions of a grape variety, trying Malbec from a less common region like Suisun Valley can be an exciting adventure. It can offer a different flavor profile compared to Malbecs from more traditional regions.

Food Pairing:

Malbec is a versatile wine known for its medium to full body and rich, dark fruit flavors. Suisun Valley Malbecs can pair well with a variety of foods, including grilled meats, hearty pasta dishes, and cheeses.

Exploration:

If you’re an adventurous winemaker who enjoys exploring and discovering hidden gems, Suisun Valley Malbec can be an interesting addition to your wine collection.

Flavor Profile:

Medium bodied, mellow, fruity – raisins, fresh picked blueberries, plum, with soft, fine grained tannins, deliciously drinkable mocha notes.

Previous Season Grape Chemistry:

- Brix: 24.5

- pH: 3.29

- TA: .65gms/100ml

- Clone 9

- Planted in 2009

- Soil: Yolo, Silty Clay Loam

- VSP posititioning

Recent Comments