Hurry! Get Your Spring Orders In Before It’s Too Late!

Dear Valued Winemakers,

We hope this post finds you well and excited about the fantastic Spring products we have in store for you! As we gear up for another exciting week, we wanted to remind you that time is ticking, and we don’t want you to miss out on the opportunity to get your hands on our amazing Spring offerings.

From South Africa:

Juice Varieties: Shiraz, Merlot, Pinotage, Cabernet Sauvignon, Semillon, Chardonnay, Pinot Grigio, Chenin Blanc, Sauvignon Blanc

Fresco Juice Varieties: Cabernet Sauvignon, Pinotage, Shiraz, Sauvignon Blanc

Arrivals: Last week in April

From Chile:

Grapes Varieties: Carmenere, Cabernet Sauvignon, Cabernet Franc, Malbec, Merlot, Petite Verdot, Pinot Noir, Syrah, Chardonnay, Pinot Grigio, Sauvignon Blanc, and Viognier

Juice Varieties: Carmenere, Cabernet Sauvignon, Cabernet Franc, Cabernet/Merlot Blend, Malbec, Merlot, Petite Verdot, Pinot Noir, Syrah, Chardonnay, Pinot Grigio, Sauvignon Blanc, and Viognier.

Fresco Juice Varieties: Cabernet Sauvignon, Carmenere, Malbec, Merlot, Chardonnay, Chardonnay-Semillon, Sauvignon Blanc, Viognier

Arrivals: First week in May

Whether you’re looking for that perfect blending wine, treating yourself to something special, or simply stocking up on your favorite variety, now is the time to act! Our boats will be arriving soon and they are brimming with top-quality products waiting to be discovered. We wouldn’t want you to miss out on the fun of Spring winemaking. Don’t let procrastination steal your joy – place your order today and let the anticipation begin!

So, what are you waiting for? Join the excitement, and let’s make this Spring winemaking experience one to remember!

Thank you for choosing Musto Wine Grape Co. We truly appreciate your continued support.

Happy Winemaking!

Warmest Regards,

The Musto Crush Crew

877-812-1137

Wine Spotlight: Amorosso/Amarone Blend

One of our all time favorite Italian wine juices will be arriving in October, the Amorrosso/Amarone Blend. Sweet and bold, this wine is popular at any table. It will be arriving in early October from Italy. The Amarone fresh juice is available for pre-order and on demand pick up. The Amorosso Fresco is pre-order only. Please call 877-812-1137 to put in your order. We have a huge list of Italian wine juices for sale. Be sure to give us a call to check out what is available.

The Blend:

Amorosso/Amarone wine is a unique and highly regarded red wine produced in the Valpolicella region of Veneto, Italy. It is known for its rich, full-bodied flavor, high alcohol content, and complex aroma. Primarily made from three grape varieties: Corvina, Corvinone, and Rondinella. The grapes are carefully selected from well-maintained vineyards, and only the ripest bunches are chosen for this blend.

Appassimento:

The key step in Amarone production is the drying process, also known as “appassimento.” Instead of pressing the grapes immediately, they are spread out on wooden racks or straw mats in well-ventilated rooms, lofts, or drying chambers. During this time, they lose water content, which concentrates their sugars, flavors, and aromas. This process can reduce the weight of the grapes by 30-40%.

After the drying process, the grapes are gently crushed to release their juice. The grape skins are thick and full of flavor due to the drying process.

Winemaking Notes:

Typically, after fermentation, Amorossa/Amarone wine is aged for an extended period in oak barrels. The aging process can range from two to several years, depending on the producer’s preferences. This aging helps mellow the wine’s tannins, integrate its flavors, and develop its complex bouquet. For step by step instructions check out this blog post.

Flavor Profile:

Amorosso/Amarone wine is characterized by its deep ruby-red color, intense and complex aromas of dried fruits, dark cherries, spices, and a full-bodied, velvety texture. It is often enjoyed as a fine wine on its own or paired with hearty dishes like roasted meats, game, and aged cheeses. Due to its unique production method, Amorosso/Amarone tends to be more expensive than many other Italian wines but is highly regarded by wine enthusiasts for its exceptional quality and flavor profile.

Viva Italia!

To make an Italian wine juice order please contact us via sales@juicegrape.com or call us at 877-812-1137, follow us on Facebook, Instagram, and Youtube, or check out the Harvest Tracker and Winemaker Blog on our website- juicegrape.com.

What is the difference between Fresco Juices and Fresh Juices?

What is the difference between Fresco Juice vs. Fresh Juice?

Fresco Juices:

Ever bake a cake from a box and it came out delicious? Did you know you could do the same with winemaking?

Mondiale Fresco is proud to be the only product to offer home winemakers their own vineyard in one unique package. Each pail of juice is pre-balanced and adjusted to ensure you have the best winemaking success possible. Just warm up the juice to fermentation temperature and watch it go.

What does “pre-balanced” and “adjusted” mean?

Every season Mother Nature gives us a different wine grape harvest. Some years the acid, pH, and sugars are all in line with each other. Most times they aren’t and there needs to be some slight adjustments made pre-fermentation to ensure top wine quality. The Fresco juices are adjusted so that the acid, pH, and sugar levels are all in balance with each other. This makes for an easier fermentation and, a very pleasing wine.

Depending on the varietal of wine you choose, enzymes and tannins might be added – all pre-measured, and ready-to-go, just open the packet and add to the pail. These add-ons help with wine clarity and mouthfeel, contributing to the “taste like made from scratch”, or in this case, as if fermented on the skins. The Fresco juices are the best juices to work with for busy winemakers. You get the juice warmed up, watch it ferment, age, and bottle.

Fresh Juices:

Fresh Juices come straight from the press!

Our fresh juices are from the grapes that are crushed, destemmed, and pressed right into the pails. For white wine, this is as if you were crushing and pressing yourself. For red wine the grapes are run through a heat or “hot” press in order to extract the color. Once these pails come up to temperature they can kick off because of the native yeast from the original grapes, or you can kill the native yeast and pitch your own yeast to ensure a more successful fermentation. Either way you are working with the fresh juice, not from concetrate. A delicous wine can be on your table as soon as Christmas!

So what is the difference?

The Fresh Juices are the straight from the press. The Fresco juices are straigth from the press, but pre-balanced and have a few additions made to them to make fermentation easier on the winemaker.

Either way you have delicious wine in the making!

To make an order please contact us via sales@juicegrape.com or call us at 877-812-1137, follow us on Facebook, Instagram, and Youtube, or check out the Harvest Tracker and Winemaker Blog on our website- juicegrape.com.

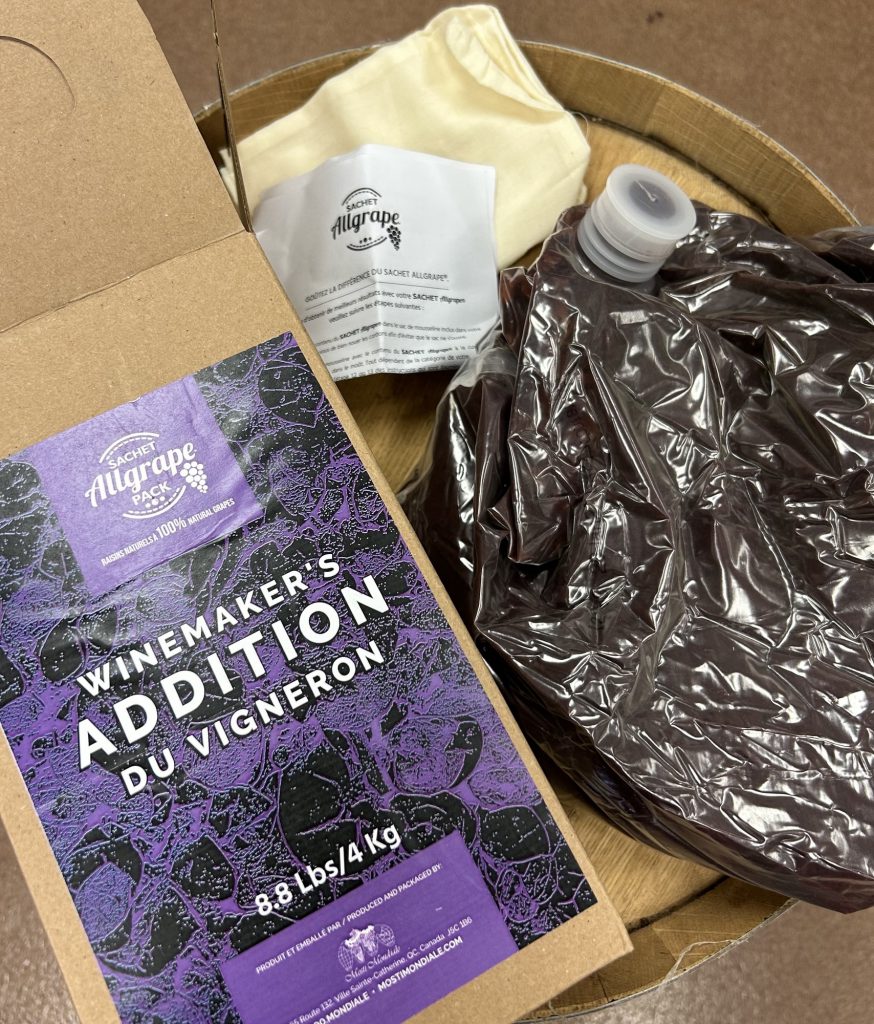

Upgrade Your Winemaking Juice with the AllGrape Pack!

Upgrade Your Winemaking Juice with the AllGrape Pack!

Making from Fresh Juice or Wine Kits produces a fantastic wine, but can sometimes be lacking in tannins, color, flavor, and mouthfeel. This isn’t the winemaker’s fault, this is becasue these types of product do not get ample time on the grape skins to give the wine that extra kick of complexity.

Lucky for you, We Have a Solution! Enter the AllGrape Pack

The AllGrape pack® contains 100% grapes, NO Fillers, NO sweeteners just 100% pasteurized crushed and destemmed grapes as “Mother Nature” intended!

Packed in a sterile, shelf-stable, bag in a box…taste the real Allgrape® difference.

Add it to your Fresh Wine Juice or Wine Kit and see a significant increase in the Flavor Profile, Tanninic Structure, and Mouthfeel in your Juice Wine!

It tastes as if you made wine from grapes!

Sam & Christina did an experiment with Chilean Merlot this Spring. We did one pail with the AllGrape pack and one pail without it. We couldn’t believe the difference! We believe in the product so much so that we discounted it so it’s easier to test out for yourselves. You won’t be disapointed. But hurry because this sale will only last until Novemeber!

FALL SPECIAL!

$33.00 – NOW $25.00

To make a wine juice order or if you have any questions about the AllGrape pack please contact us via sales@juicegrape.com or call us at 877-812-1137, follow us on Facebook, Instagram, and Youtube, or check out the Harvest Tracker and Winemaker Blog on our website- juicegrape.com.

The Italians are Coming!!

There are several compelling reasons to consider

making Italian wine from Musto’s Italian juices.

Variety:

Italy is one of the world’s largest wine producers, and it boasts an incredible variety of wine styles, grape varieties, and regions. Whether you prefer red, white, sparkling, or dessert wines, Italy offers an extensive range to explore.

Terroir:

Italy’s diverse geography, climate, and soils contribute to a rich tapestry of terroirs. Each wine region has its own unique characteristics, producing wines with distinct flavors and profiles.

Food Pairing:

Italian wines are known for their versatility and ability to complement a wide range of cuisines. Whether you’re enjoying pizza, pasta, seafood, or fine Italian cuisine, there’s an Italian wine that pairs beautifully with it.

Quality:

Italy has a long history of winemaking, and many Italian wineries are dedicated to producing high-quality wines. Italy has a significant number of prestigious wine regions and producers, including those in Tuscany, Piedmont, Puglia, and Veneto.

Heritage:

Italy has a deep cultural and historical connection to winemaking. This heritage is reflected in the traditions, techniques, and dedication of Italian winemakers.

Uniqueness:

Italy is home to several unique and iconic wine styles, such as Barolo, Amarone, Chianti, Prosecco, and Brunello di Montalcino, among others. Exploring these wines can be a delightful and enriching experience.

Whether you’re looking for a bold red wine like Barolo, a crisp white like Pinot Grigio, Italy has something to offer for every palate and occasion!

Musto Wine Grape will be receiving Italian wine juices this October! See below for a full list of what is available from Italy this fall.

Musto Wine Grape Italian Juice Offerings:

Fresh Italian Juices:

Amarone

Barolo

Brunello

Chianti

Dolchetto

Lambrusco

Montelpulciano

Moscato

Nebbiolo

Nero D’Avola

Pinot Grigio

Sangiovese

Trebbiano

Valpolicella

Italian Fresco Juices (pre-order only):

Amorosso (Amarone)

Granbarile (Barolo)

Castel del Papa

Il Toscano (Chianti)

Lambrusco

Merlot

Montelpulciano

Nebbiolo

Primitivo

Sangiovese

Pinot Grigio

Trebbiano

To make an order please contact us via sales@juicegrape.com or call us at 877-812-1137, follow us on Facebook, Instagram, and Youtube, or check out the Harvest Tracker and Winemaker Blog on our website- juicegrape.com.

Wine Spotlight: Lanza-Musto Vineyards Malbec

Lanza-Musto Suisun Valley Malbec is a wine that brings velvety sweetness and dark complexity to the table.

Suisun Valley, located in Solano County, California, is not traditionally known for Malbec wine production like some other regions, but it does have a small and growing reputation for producing high quality Malbec wines. If you’re considering buying Suisun Valley Malbec grapes, here are some reasons to consider:

Unique Terroir:

Suisun Valley’s terroir, characterized by its climate, soil, and topography, offers a unique and distinct environment for grape cultivation. While it may not have the recognition of regions like Argentina (known for Malbec), this uniqueness can result in wines with a different expression of the Malbec grape.

Varietal Exploration:

If you enjoy exploring different expressions of a grape variety, trying Malbec from a less common region like Suisun Valley can be an exciting adventure. It can offer a different flavor profile compared to Malbecs from more traditional regions.

Food Pairing:

Malbec is a versatile wine known for its medium to full body and rich, dark fruit flavors. Suisun Valley Malbecs can pair well with a variety of foods, including grilled meats, hearty pasta dishes, and cheeses.

Exploration:

If you’re an adventurous winemaker who enjoys exploring and discovering hidden gems, Suisun Valley Malbec can be an interesting addition to your wine collection.

Flavor Profile:

Medium bodied, mellow, fruity – raisins, fresh picked blueberries, plum, with soft, fine grained tannins, deliciously drinkable mocha notes.

Previous Season Grape Chemistry:

- Brix: 24.5

- pH: 3.29

- TA: .65gms/100ml

- Clone 9

- Planted in 2009

- Soil: Yolo, Silty Clay Loam

- VSP posititioning

To make an order please contact us via sales@juicegrape.com or call us at 877-812-1137, follow us on Facebook, Instagram, and Youtube, or check out the Harvest Tracker and Winemaker Blog on our website- juicegrape.com.

Newbie Winemaker Gifts

Do you have a newbie winemaker in your life you need to get a gift for?

Maybe you are the newbie winemaker, and you need to know what to ask for this holiday season!

Either way, we have prepared a basic gift buying guide for you, to simplify the just-getting-started-winemaking process!

1. CARBOYS. The average home winemaker will never complain about having too many carboys – it just means more vessels to make wine in! You can get them in 3, 5, or 6 gallon formats. It’s always a good idea to get one of each to help accommodate varying volumes.

2. DEMIJOHNS. A more traditional vessel to make wine in, these can hold more volume AND not to mention it, but they are pretty cool looking. You can get them with or without a spigot at the bottom.

3. REFRACTOMETER. These devices are used to check the amount of sugar in grapes, and are indispensable to the serious home winemaker who is also starting to grow their own grapes as well – it helps to tell them when they should harvest!

4. OAK CHIPS. As a great way to play around with flavor, oak chips help the newbie winemaker to get a feel for what oak does to a wine as it ages without the investment in, and care for a full sized barrel. There’s a lot to learn when it comes to proper barrel maintenance, so adding oak chips is a perfect way to get the color and flavor dynamics of working with oak.

5. SIPHON. If your newbie winemaker wants to move beyond using a funnel or mouth siphoning to transfer their wine, an autosiphon will help to elevate them to the next level. It’s going to make their life a lot less messy and will take up less of their time to move their wine from vessel to vessel.

6. GIFT CERTIFICATE. Last but not, least! Purchase a gift certificate and your winemaker can put it towards anything they want. Classes, equipment, grapes, juices, you name it!

Musto Wine Grape Company is here to help! We are New England’s largest supplier for home winemaking products and services. You can get set up with all of your juice, grape and equipment needs and have you on track to making your own perfect pairing for next fall! Visit juicegrape.com or give us a call at (877) 812 – 1137 to learn more. We look forward to hearing from you!

Winemaking with Italian juices

Let’s make wine from Italian juice… at home!

Many winemakers wait all year for their annual Italian juice pickup at Musto. Despite the fact that they may be able to find some of these juices from California, they look forward to knowing that they will be able to make wine that hails from Italy itself.

There’s so many juices to choose from:

- Amarone- cooked cherries, dark plums, cherry liqueur

- Barolo- tannic, rose aroma

- Brunello- cherry, blackberry, tannic

- Chianti- red fruit, dried herbs, herbaceous

- Dolcetto- plum, blackberry, cocoa

- Lambrusco- fruity, blackberry, bright red fruits

- Montepulciano- red plum, thyme, baking spices

- Moscato- sweet, fruity, aromatic

- Nebbiolo- rose, cherry, leather

- Nero D’Avola- cherry, plum, licorice, tobacco

- Pinot Grigio- lemon, lime green apple, bright and crisp

- Sangiovese- tart cherry, strawberry, plum

- Trebbiano- peach, lemon, apple

- Valpolicella- cherry, cinnamon, chocolate

For winemakers who don’t have access to a crusher, destemmer, or press, making wine from Italian juices is a great way to get the joy of making your own wine with less steps and less mess.

So how can you start making your own wine from Italian juices? Follow these steps and you’ll be on your way!

- Choose an Italian variety that speaks to you.

- Come to Musto Wine Grape and pick up your pail of juice.

- Bring it home, pop open that lid, and add 1/4 tsp potassium metabisulfite to it. Add pectic enzyme if you’re going to (5 drops per gallon of juice). Give it a stir.

- Allow it to come up to room temperature – we’re talking 60 degrees or so.

- Choose your fermentation vessel: will you keep it in pails or ferment in a carboy or demijohn? Make sure everything is clean and sanitized. *Be sure there is enough room to account for fermentation foaming*

- If you are going to add fermentation tannins or additives (like oak dust, Booster Rouge, Booster Blanc) you can add that now. *Note: do not add tannins such as FT Rouge within 8 hours of adding enzyme*

- Pitch the yeast once the temperature has reached at least 60F. Yeast strain choices will vary depending on the juice you choose – ask a winemaker at Musto Wine Grape for a strain recommendation for the varietal you’re making. Follow the yeast starter directions explicitly. Be very careful of temperatures, never adding yeast if there is more than a 18 degree difference between the yeast starter liquid and the juice.

- Carefully monitor the fermentation by checking Brix levels daily. Add yeast nutrients as needed if you choose to do so.

- If you are adding malolactic cultures to your wine, you may also chose to do this at 1/3 Brix depletion. If using a malolactic nutrient (Opti-Malo Plus) with the bacterial culture, hydrate the nutrient in a separate container from the bacteria and add to the must directly before the addition of the bacteria. Follow all directions on the bacteria and nutrient packets explicitly.

- When the fermentation is complete, rack off the lees and continue aging. Many Italian wines are aged with oak – if you choose to do this, you can do so in oak barrels or with oak alternatives (such as chips or staves).

And there you have it! Delicious Italian wine that you made in your own home. There’s nothing more rewarding than having a glass of wine you made with juice from a reliable source.

Feeling inspired? Come down to Musto Wine Grape and pick up some Italian juice. But don’t wait too long – we are fast approaching the end of harvest time. Pick up everything you need and and be on your way to kicking back as you sip on a glass of homemade Italian wine. Who knows, maybe you’ll even make Frank’s Chicken Fettuccini Alfredo to accompany it!

Setting up your stainless steel tank

Once the home winemaker has mastered the art of getting just the right amount of wine into dozens of different sized carboys, they may be wondering if there is an easier way to ferment and bulk age their wine. Enter the stainless steel tank!

While getting a stainless tank may seem like a big next step, it’s likely one of the best decisions you will make, assuming production levels are high enough. If you’re a home winemaker who has a couple carboys sitting in the cellar, your goal probably isn’t a larger tank. But if you’re making anything more than that, it may just make your life that much easier (and fun!)

A variety of sizes

Stainless steel tanks come in many sizes, from 100 liters (26 gallons) to 10,000 liters or more! Unless you’re looking to start their own large scale commercial winery, you’ll likely start your search in the 100L+ range.

Variable capacity or fixed volume

Part of the beauty of stainless tanks is that unlike carboys, demijohns, and barrels, they are oftentimes variable capacity. What does this mean? It means you don’t have to worry about constantly topping up, blending other wines into your batch to allow it to reach the neck of the vessel, the threat of oxidation, or employing inert gas to keep the head space at the top of the vessel blanketed. Some winemakers prefer fixed capacity tanks, but again, the downside is that you really need to stay on top of keeping them full the entire time you’re bulk aging.

Time to set up your stainless steel tank

Setting up your tank is very simple to do. The basic setup will include a stand, valves, tasting valve, and maybe a thermometer and a thermowell. The tank may come with a stand or leveling feet which elevate it from the ground. Even the most simplistic, small tank may come with these, though some will only be basic enough that they get placed directly onto the floor or a pallet. The smallest tanks will not have a manway, since you can easily reach in from the top for cleaning or extracting the juice or must post fermentation. Some will have a valve on the bottom and some will not.

What else might I need to set up on my tank?

-

A manway

-

1 or more valves

-

Sight gauge (plastic tube on side of tank indicating volume in tank)

-

Racking port and drainage port (higher and lower ports, respectively)

-

Gaskets and clamps (most common are 1.5″ / 2″ / 2.5″)

-

Gasket and pump (for variable capacity tank)

Musto Wine Grape is happy to offer a wide range of Marchisio stainless steel tanks, from 100L capacity onward. Come see us and we will be happy to speak with you in detail about what tank is the best for you!

SOS: Sluggish/stuck fermentation

Many a winemaker has lamented the dreaded stuck fermentation. With so much to deal with during harvest time, the last thing you should be worried about is a ferment that has just up and quit. But sometimes it happens – knowing what to do when it does will be a life saver during an otherwise potentially unfortunate moment in a wine’s life. We’re here to walk you through how to handle this, what to do, and most importantly, how to do it.

Step 1: Think about why it may have gotten stuck

This is going to help you moving forward, both with this wine and with future ferments. Was there too much sugar in the juice or must to begin with? Was the fermentation temperature too cool or too hot? Did you choose a yeast that doesn’t do well with high sugar levels? Were nutrient levels too low?

Considerations before restarting

- Adding lysozyme can halt spoilage organisms which are often present in sluggish or stuck fermentations

- Resuke can lower toxin levels that have accumulated which will give you a better chance for a healthy restart. If you add this you will rack off of it 1-2 days later.

- Incorporate Go-Ferm and Go-Ferm Protect Evolution to ensure health of ensuing restarting fermentation

- Carefully choose what yeast you will re-pitch with. 43, 43 Restart, Fermivin Champion, K1 (V1116), Vin 13, BC, and DV10 are great choices.

Step 2. Add a complex yeast nutrient

This is going directly into the stuck wine tank. If you think you may have a spoilage bacteria problem, this is the time you would be adding lysozyme.

Step 3. Combine equal parts stuck wine and water in another vessel

This is known as the “mother restart tank.” At this moment it will be totaling 2% of whole volume.

Step 4. Rehydrate yeast nutrient + yeast as you would when pitching yeast the first time

This is the exact same process you did during the initial yeast pitch.

Step 5. Add the yeast to the mother restart tank

As always, there should be a <18F difference between the yeast mixture and the mother restart tank liquid temperature.

Step 6. Add 10% of the stuck wine to the starter culture

Wait 20-30 minutes.

Step 7. Add 20% of the stuck wine to the starter culture

Wait 20-30 minutes.

Step 8. Repeat until the remainder of the stuck wine has been added to the mother restart tank

Don’t skimp on waiting the 20-30 minutes at each of the following steps. Give it time to acclimate!

Recent Comments