Hurry! Get Your Spring Orders In Before It’s Too Late!

Dear Valued Winemakers,

We hope this post finds you well and excited about the fantastic Spring products we have in store for you! As we gear up for another exciting week, we wanted to remind you that time is ticking, and we don’t want you to miss out on the opportunity to get your hands on our amazing Spring offerings.

From South Africa:

Juice Varieties: Shiraz, Merlot, Pinotage, Cabernet Sauvignon, Semillon, Chardonnay, Pinot Grigio, Chenin Blanc, Sauvignon Blanc

Fresco Juice Varieties: Cabernet Sauvignon, Pinotage, Shiraz, Sauvignon Blanc

Arrivals: Last week in April

From Chile:

Grapes Varieties: Carmenere, Cabernet Sauvignon, Cabernet Franc, Malbec, Merlot, Petite Verdot, Pinot Noir, Syrah, Chardonnay, Pinot Grigio, Sauvignon Blanc, and Viognier

Juice Varieties: Carmenere, Cabernet Sauvignon, Cabernet Franc, Cabernet/Merlot Blend, Malbec, Merlot, Petite Verdot, Pinot Noir, Syrah, Chardonnay, Pinot Grigio, Sauvignon Blanc, and Viognier.

Fresco Juice Varieties: Cabernet Sauvignon, Carmenere, Malbec, Merlot, Chardonnay, Chardonnay-Semillon, Sauvignon Blanc, Viognier

Arrivals: First week in May

Whether you’re looking for that perfect blending wine, treating yourself to something special, or simply stocking up on your favorite variety, now is the time to act! Our boats will be arriving soon and they are brimming with top-quality products waiting to be discovered. We wouldn’t want you to miss out on the fun of Spring winemaking. Don’t let procrastination steal your joy – place your order today and let the anticipation begin!

So, what are you waiting for? Join the excitement, and let’s make this Spring winemaking experience one to remember!

Thank you for choosing Musto Wine Grape Co. We truly appreciate your continued support.

Happy Winemaking!

Warmest Regards,

The Musto Crush Crew

877-812-1137

Wine Spotlight: Amorosso/Amarone Blend

One of our all time favorite Italian wine juices will be arriving in October, the Amorrosso/Amarone Blend. Sweet and bold, this wine is popular at any table. It will be arriving in early October from Italy. The Amarone fresh juice is available for pre-order and on demand pick up. The Amorosso Fresco is pre-order only. Please call 877-812-1137 to put in your order. We have a huge list of Italian wine juices for sale. Be sure to give us a call to check out what is available.

The Blend:

Amorosso/Amarone wine is a unique and highly regarded red wine produced in the Valpolicella region of Veneto, Italy. It is known for its rich, full-bodied flavor, high alcohol content, and complex aroma. Primarily made from three grape varieties: Corvina, Corvinone, and Rondinella. The grapes are carefully selected from well-maintained vineyards, and only the ripest bunches are chosen for this blend.

Appassimento:

The key step in Amarone production is the drying process, also known as “appassimento.” Instead of pressing the grapes immediately, they are spread out on wooden racks or straw mats in well-ventilated rooms, lofts, or drying chambers. During this time, they lose water content, which concentrates their sugars, flavors, and aromas. This process can reduce the weight of the grapes by 30-40%.

After the drying process, the grapes are gently crushed to release their juice. The grape skins are thick and full of flavor due to the drying process.

Winemaking Notes:

Typically, after fermentation, Amorossa/Amarone wine is aged for an extended period in oak barrels. The aging process can range from two to several years, depending on the producer’s preferences. This aging helps mellow the wine’s tannins, integrate its flavors, and develop its complex bouquet. For step by step instructions check out this blog post.

Flavor Profile:

Amorosso/Amarone wine is characterized by its deep ruby-red color, intense and complex aromas of dried fruits, dark cherries, spices, and a full-bodied, velvety texture. It is often enjoyed as a fine wine on its own or paired with hearty dishes like roasted meats, game, and aged cheeses. Due to its unique production method, Amorosso/Amarone tends to be more expensive than many other Italian wines but is highly regarded by wine enthusiasts for its exceptional quality and flavor profile.

Viva Italia!

To make an Italian wine juice order please contact us via sales@juicegrape.com or call us at 877-812-1137, follow us on Facebook, Instagram, and Youtube, or check out the Harvest Tracker and Winemaker Blog on our website- juicegrape.com.

What is the difference between Fresco Juices and Fresh Juices?

What is the difference between Fresco Juice vs. Fresh Juice?

Fresco Juices:

Ever bake a cake from a box and it came out delicious? Did you know you could do the same with winemaking?

Mondiale Fresco is proud to be the only product to offer home winemakers their own vineyard in one unique package. Each pail of juice is pre-balanced and adjusted to ensure you have the best winemaking success possible. Just warm up the juice to fermentation temperature and watch it go.

What does “pre-balanced” and “adjusted” mean?

Every season Mother Nature gives us a different wine grape harvest. Some years the acid, pH, and sugars are all in line with each other. Most times they aren’t and there needs to be some slight adjustments made pre-fermentation to ensure top wine quality. The Fresco juices are adjusted so that the acid, pH, and sugar levels are all in balance with each other. This makes for an easier fermentation and, a very pleasing wine.

Depending on the varietal of wine you choose, enzymes and tannins might be added – all pre-measured, and ready-to-go, just open the packet and add to the pail. These add-ons help with wine clarity and mouthfeel, contributing to the “taste like made from scratch”, or in this case, as if fermented on the skins. The Fresco juices are the best juices to work with for busy winemakers. You get the juice warmed up, watch it ferment, age, and bottle.

Fresh Juices:

Fresh Juices come straight from the press!

Our fresh juices are from the grapes that are crushed, destemmed, and pressed right into the pails. For white wine, this is as if you were crushing and pressing yourself. For red wine the grapes are run through a heat or “hot” press in order to extract the color. Once these pails come up to temperature they can kick off because of the native yeast from the original grapes, or you can kill the native yeast and pitch your own yeast to ensure a more successful fermentation. Either way you are working with the fresh juice, not from concetrate. A delicous wine can be on your table as soon as Christmas!

So what is the difference?

The Fresh Juices are the straight from the press. The Fresco juices are straigth from the press, but pre-balanced and have a few additions made to them to make fermentation easier on the winemaker.

Either way you have delicious wine in the making!

To make an order please contact us via sales@juicegrape.com or call us at 877-812-1137, follow us on Facebook, Instagram, and Youtube, or check out the Harvest Tracker and Winemaker Blog on our website- juicegrape.com.

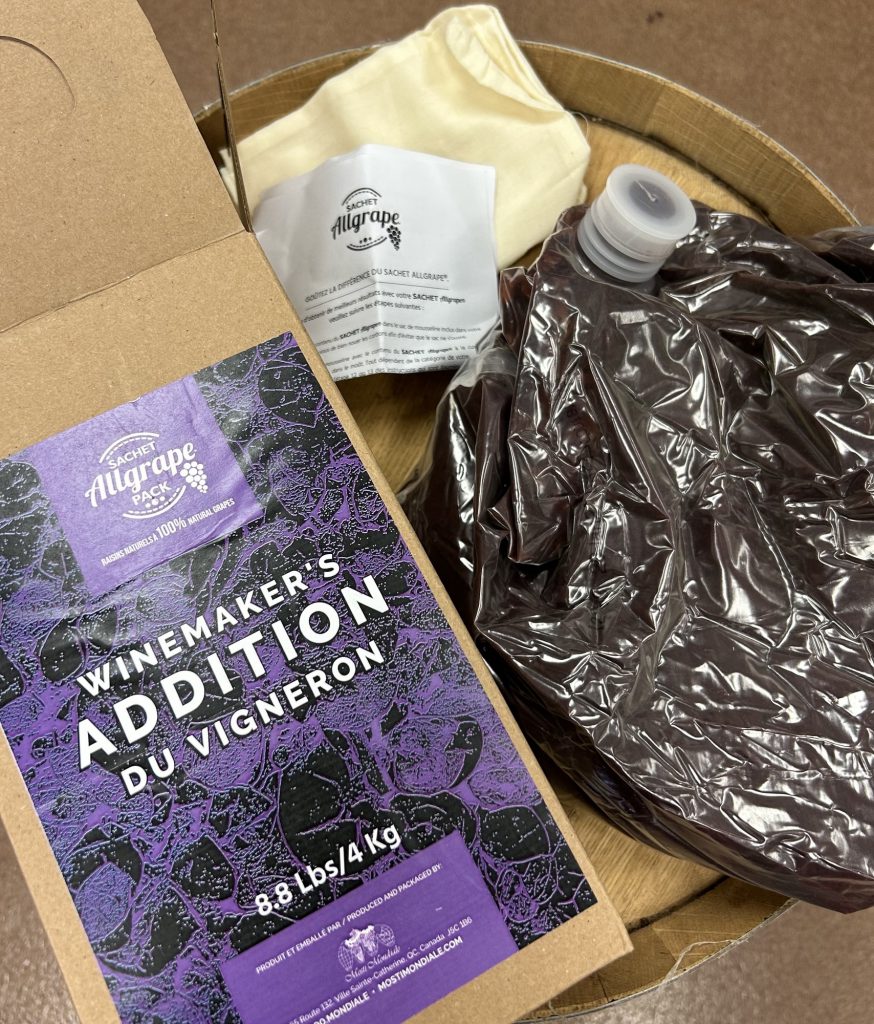

Upgrade Your Winemaking Juice with the AllGrape Pack!

Upgrade Your Winemaking Juice with the AllGrape Pack!

Making from Fresh Juice or Wine Kits produces a fantastic wine, but can sometimes be lacking in tannins, color, flavor, and mouthfeel. This isn’t the winemaker’s fault, this is becasue these types of product do not get ample time on the grape skins to give the wine that extra kick of complexity.

Lucky for you, We Have a Solution! Enter the AllGrape Pack

The AllGrape pack® contains 100% grapes, NO Fillers, NO sweeteners just 100% pasteurized crushed and destemmed grapes as “Mother Nature” intended!

Packed in a sterile, shelf-stable, bag in a box…taste the real Allgrape® difference.

Add it to your Fresh Wine Juice or Wine Kit and see a significant increase in the Flavor Profile, Tanninic Structure, and Mouthfeel in your Juice Wine!

It tastes as if you made wine from grapes!

Sam & Christina did an experiment with Chilean Merlot this Spring. We did one pail with the AllGrape pack and one pail without it. We couldn’t believe the difference! We believe in the product so much so that we discounted it so it’s easier to test out for yourselves. You won’t be disapointed. But hurry because this sale will only last until Novemeber!

FALL SPECIAL!

$33.00 – NOW $25.00

To make a wine juice order or if you have any questions about the AllGrape pack please contact us via sales@juicegrape.com or call us at 877-812-1137, follow us on Facebook, Instagram, and Youtube, or check out the Harvest Tracker and Winemaker Blog on our website- juicegrape.com.

Available for pick up this week (9/18-9/24)

Hello Winemakers,

I hope this message finds you well. We are thrilled to share some exciting news from our vineyard as we kick off this year’s grape harvest season.

The conditions this year have been wonderful, resulting in a crop of the finest grapes we’ve seen in a long time. We wanted to give you a sneak peek into what’s happening here at Musto Wine Grape this week.

Grape Varieties: Our vineyards boasts a variety of grape types, each with its unique characteristics. This year, we have seen exceptional growth and quality across the board. From the bold and robust reds to the crisp and refreshing whites, our grapes are thriving.

- Alicante, Cabernet, Chardonnay, Barbera, Black Muscat, Grenache, Merlot, Malvasia Bianca, Muscat, Old Vine Zinfandel, Petite Sirah, Petite Verdot, Pinot Noir, Sangiovese, Symphony, Syrah, Thompson Seedless, Touriga Nacional, Zinfandel, and Zinderella

Wine Juices: We have a great selection of wine juices with fresh pails arriving daily. We are fully stocked with our California juice pails. The Italian juices will start to arrive in the first week in October, along with the pre-order Fresco juices.

- Alicante, Barbera, Cabernet Sauvignon, Chianti, Grenache, Merlot, Mixed Black, Old Vine Zinfandel, Pinot Noir, Red Blend, Sangiovese, Zinfandel, Black Muscat (Rosé), Chardonnay, French Colombard, Pinot Grigio, and White Zinfandel (Rosé), and more!!

- Reminder: Fresco juices must be ordered by 9/25!

Harvest Updates: Everything is ripening beautifully, promising an outstanding flavor profile.

- Suisun Valley will not start harvesting until the end of this week. We should start to see their grapes arrive in late September / early October. *A late addition* to the harvest menu – we will have Pinot Noir from Suisun Valley!! There are only a few boxes available. Give us a call to secure your PN today!

- Washington State Pinot Noir is harvesting this week. We might see it as early as 9/25. The Washington Cabernet, Merlot, and Cabernet Franc should start harvest in the next 2 weeks.

Produce: Every year Stevie works hard to bring you seasonally delish produce. This week we will have more Olives, Figs, and Plums available for purchase. Please call ahead if you have your heart set on anything. We will have limited quantities.

- Olives arriving 9/21

- Figs arriving 9/22

- Plums here

Winemaker In Your Pocket: Musto Wine Grape and Frank Renladi put together online courses you can access from anywhere! Check out our online classes via our sister site WinemakingInstructions.com.

- Full Winemaking Course – Over 46 videos of content!

- Online Winemaker Bootcamp

- Freebies

Our team is hard at work, carefully monitoring the grapes’ progress. We can’t wait to start turning these exceptional grapes into the finest wines! Stay tuned for more updates as the harvest progresses. We’ll be sharing behind-the-scenes glimpses, tasting notes, and more exciting news in the weeks to come.

Thank you for being a part of our journey at Musto Wine Grape. We look forward to sharing the fruits of this year’s labor with you and raising a glass together to celebrate the extraordinary flavors of our grapes.

Cheers to a bountiful harvest!

Christina & The Musto Crush Crew

Musto Wine Grape Co. / WinemakingInstructions.com

www.juicegrape.com / 877-812-1137 / cmusto@juicegrape.com

Wine Spotlight: Lanza-Musto Vineyards Malbec

Lanza-Musto Suisun Valley Malbec is a wine that brings velvety sweetness and dark complexity to the table.

Suisun Valley, located in Solano County, California, is not traditionally known for Malbec wine production like some other regions, but it does have a small and growing reputation for producing high quality Malbec wines. If you’re considering buying Suisun Valley Malbec grapes, here are some reasons to consider:

Unique Terroir:

Suisun Valley’s terroir, characterized by its climate, soil, and topography, offers a unique and distinct environment for grape cultivation. While it may not have the recognition of regions like Argentina (known for Malbec), this uniqueness can result in wines with a different expression of the Malbec grape.

Varietal Exploration:

If you enjoy exploring different expressions of a grape variety, trying Malbec from a less common region like Suisun Valley can be an exciting adventure. It can offer a different flavor profile compared to Malbecs from more traditional regions.

Food Pairing:

Malbec is a versatile wine known for its medium to full body and rich, dark fruit flavors. Suisun Valley Malbecs can pair well with a variety of foods, including grilled meats, hearty pasta dishes, and cheeses.

Exploration:

If you’re an adventurous winemaker who enjoys exploring and discovering hidden gems, Suisun Valley Malbec can be an interesting addition to your wine collection.

Flavor Profile:

Medium bodied, mellow, fruity – raisins, fresh picked blueberries, plum, with soft, fine grained tannins, deliciously drinkable mocha notes.

Previous Season Grape Chemistry:

- Brix: 24.5

- pH: 3.29

- TA: .65gms/100ml

- Clone 9

- Planted in 2009

- Soil: Yolo, Silty Clay Loam

- VSP posititioning

To make an order please contact us via sales@juicegrape.com or call us at 877-812-1137, follow us on Facebook, Instagram, and Youtube, or check out the Harvest Tracker and Winemaker Blog on our website- juicegrape.com.

🍇🍷 Exciting News! The Black Muscat Wine Grapes Have Arrived! 🍇🍷

The dock is buzzing with excitement as we welcome the arrival of our beautiful Black Muscat wine grapes, ripened to perfection under the warm sun and nurtured with care.

🍇 Black Muscat

When it comes to grapes, we often think of the popular varieties like Cabernet Sauvignon, Merlot, or Zinfandel. However, tucked away in the world of vineyards is a gem that’s lesser-known but equally delightful – Black Muscat grapes. These grapes are a true delicacy, offering a unique combination of intense flavor, striking appearance, and a rich history. Black Muscat makes a fantastic sweet rosé, light red wine, and is a great base for Raki. In this post, we’ll dive into the fascinating world of Black Muscat grapes and explore what makes them so special.

🌞 A Brief History

Black Muscat grapes have their origins in the Mediterranean and are closely related to the Muscat family of grapes, known for their aromatic and sweet qualities. These grapes have a long and storied history, dating back thousands of years to ancient times when they were cultivated for wine production and used for medicinal purposes.

🍷 Flavor Profile

Black Muscat grapes are known for their stunning appearance. They are a large to medium-sized, round or oval in shape, and have a deep black or purple-black skin. When you hold a bunch of Black Muscat grapes in your hand, you can’t help but be captivated by their dark, enchanting beauty. The real magic of Black Muscat grapes lies in their flavor. These grapes are renowned for their intense aromatics and sweetness.

IN STOCK FOR THIS WEEKEND:

- Grapes: Grenache Noir, Grenache Blanc, Black Muscat, Muscat, Pinot Noir, Tempranillo, Teroldego, Barbera, Cabernet, Merlot, Zinfandel, Old Vine Zinfandel, Mettler Pinot Grigio, Mettler Grenache, Alicante, and Thompson Seedless

- Juices: Cabernet Sauvignon, Merlot, Zinfandel, Grenache, Black Muscat, Mixed Black, Petite Sirah, Pinot Noir, Ruby Cabernet, Syrah, Chardonnay, Muscat, Pinot Grigio, Riesling, Sauvignon Blanc, Thompson Seedless, Viognier, and White Zinfandel

- Always call ahead to make sure you have the most up to date stock information!

Raki & Black Muscat:

Additionally, to wine – Black Muscat is a great grape to use for the drink Raki. Raki is the National drink of Turkey. It is also a popular drink through the Baltic regions and in Albania.

Raki is a traditional alcoholic beverage that is popular in several countries, especially in the Mediterranean region, including Turkey, Greece, Albania, and parts of the Balkans. It is an anise-flavored spirit with a strong, distinctive taste. The production process of raki typically involves several steps:

- Fermentation of Grapes or Other Fruits: Raki can be made from a variety of fruits, with grapes being the most common choice. Black Muscat has gained in popularity over the years to be the preferred grape to use. The first step is to crush and juice the fruit, which is then fermented. Yeast is often added to initiate the fermentation process, converting the sugars in the fruit into alcohol. This initial fermentation usually takes a few weeks.

- Distillation: After fermentation, the liquid is distilled to increase its alcohol content. The traditional method involves using a special copper pot still called a “degirmen” in Turkey or “rakia” in Greece. The fermented fruit mash is heated, and the alcohol vapor is collected and condensed to produce a high-proof spirit. The distillation process is usually repeated to ensure a higher alcohol concentration.

- Anise Flavoring: Anise seeds or aniseed are an essential ingredient in raki production. These seeds are typically crushed or ground, and the resulting powder is added to the distilled alcohol. This gives raki its characteristic licorice-like flavor and cloudy appearance when mixed with water. The anise-flavored alcohol is allowed to rest for a period, allowing the flavors to meld.

- Dilution: Raki is typically consumed by diluting it with water, which also causes it to turn cloudy due to the anise oils becoming less soluble. The ratio of water to raki can vary according to personal preference but is often around 1:1 or 2:1 (water to raki).

- Bottling and Aging: Some raki may be aged in wooden barrels for a short period to mellow its flavors, although this is less common than with other spirits like whiskey or brandy. Once the aging process is complete, the raki is typically filtered and then bottled for sale.

It’s important to note that the production methods and ingredients may vary from one region to another, and there may be slight variations in the production process. Also, the alcoholic content of raki can vary, but it is generally around 40-45% alcohol by volume.

Enjoyed primarily as an aperitif or as an accompaniment to meals, raki has a strong cultural significance in the countries where it is popular, often being consumed during social gatherings and special occasions.

Black Muscat & Rosé:

On the nose there is passion fruit, guava, sweet strawberry, sweet cherry, and papaya. The aromatics continue through the palate with a touch of crisp acidity. As a dry wine this light bodied Rose is full of complexity and flavor. If you’re more of a sweet winemaker, adding about 1-2% Residual sugar to this wine would make for a very aromatic and balanced sweet wine.

Black Muscat Winemaking Recipe:

- Crush the Black Muscat into vat

- Add Potassium Meta to kill native yeast, let sit for 12 hours

- Add Cinn Free, stir must, let sit for another 12 hours

- Press juice after 24 hours on the skins

- Add Booster Blanc and Opti White (dilute in spring water, mix like pancake mix, dump into must, mix up)

- Pitch yeast after 24 hrs on skins, make sure juice is at 65 degrees. If not let it warm up. Use VIN13 yeast.

- Next Day: Add Fermaid O

- Monitor Brix levels daily

- At 1/3 of a drop in Brix (10-8 Brix) add Fermaid K

Please Note:

The color might be light. It darkened up over time. And if it doesn’t darken up enough to your liking, I have some “pixie dust” that will help with the color during the aging process. Also, after fermentation I added Noblesse at my first racking. This is because I thought the acid was a little high and it helped soften the mouthfeel. Every year is different, so you might not need to do this. Taste it after fermentation and then decide.

If you are interested in making Black Muscat wine and having any questions please feel free to reach out to our winemaking professionals via phone or email – 877-812-1137 or sales@juicegrape.com.

Don’t forget about our Winemaking Classes…

Hands-On Winemaking: Back by popular demand is our Winemaker Bootcamp. The September Class will start Saturday September 16th, 2023 at 9:00AM – 12:00PM (runs for 5 weeks). The October Class will start on Saturday October 21st, 2023 at 9:00AM – 12:00PM (runs for 5 weeks). Make sure to sign up via the website or email cmusto@juicegrape.com if you are interested. There is only 1 space left in the September class and only 2 spaces left in the October class!

Winemaker In Your Pocket: Musto Wine Grape and Frank Renladi put together online courses you can access from anywhere! Check out our online classes via our sister site WinemakingInstructions.com.

We look forward to seeing you at pick up this season! 😊

Cheers!

Christina & The Musto Crush Crew

Musto Wine Grape Co. / WinemakingInstructions.com

The most anticipated time of the year is finally upon us – Wine Season is HERE!

Hello Winemakers,

I’m sure you are itching to get back into the winemaking process. It’s the most exciting time of year in our opinion!

The art of winemaking is truly remarkable and allows us to witness transformative magic unfolding right before our eyes. Just imagine the symphony of aromas that will fill the air as the grapes are crushed, releasing their juices, and bringing forth the promise of a beautiful vintage. Picture the vibrant colors dancing in the fermenters, as the yeasts work their magic, transforming sugar into alcohol. And oh, the joy of witnessing the first bubbles forming during fermentation, a sure sign that our wine is well on its way.

With every batch, we have the opportunity to experiment and refine our craft, constantly pushing the boundaries of what is possible in winemaking. Get excited to make a wine you will love this season!

Here’s what you can look forward to this week:

*If there is something you have your heart set on, please call ahead

- Grapes & Juices Arriving by 9/15:

- Juices: Alicante, Barbera, Cabernet Sauvignon, Chianti, Grenache, Merlot, Mixed Black, Old Vine Zinfandel, Pinot Noir, Red Blend, Sangiovese, Zinfandel, Black Muscat (Rosé) Chardonnay, French Colombard, Pinot Grigio, and White Zinfandel (Rosé).

- Grapes: Grenache, Merlot, Old Vine Zinfandel, Syrah, Teroldego, Black Muscat, Chardonnay, Fiano, Pinot Grigio, Sauvignon Blanc, Thompson Seedless, and Vermentino.

- Olives: Stevie “The Olive King” has secured the green olives for this season. He is bringing in big and small sizes, each in 16lb cases. We will have limited stock so please call ahead before you drive down. They should arrive by Friday 9/15.

- Winemaker Hours: Winemaker Sam is on vacation until September 15th. But Winemaker Barry will be in on Tuesdays, Fridays, and Saturdays to assist you with your fermentation and winemaking questions.

- Harvest Store Hours: We are officially open 7 days a week! Mon-Friday 7:00am-5:00PM, Sat 6:00AM-1:00PM, Sun 7:00AM-12:00PM

- New York/New Jersey Pick Up: D’Arrigo will be a pickup location for us in the Bronx, NY. You can pre-order with MWG and pick up your order closer to home! Ask your sales representative for more details.

- Delivery Services: MWG has an extensive delivery network. If you are interested in delivery, please ask your sales representative for more details.

- Currently In Stock (as of 9/11):

- Grapes: Grenache Noir, Grenache Blanc, Muscat, Pinot Noir, Tempranillo, Teroldego, Barbera, Alicante, and Thompson Seedless

- Juices: Cabernet Sauvignon, Merlot, Zinfandel, Grenache, Mixed Black, Petite Sirah, Pinot Noir, Ruby Cabernet, Syrah, Chardonnay, Muscat, Pinot Grigio, Riesling, Sauvignon Blanc, Thompson Seedless, Viognier, and White Zinfandel

- Always call ahead to make sure you have the most up to date stock information!

Looking ahead to Next Week:

Harvest Updates: Suisun Valley Sauvignon Blanc is around 22 Brix and the Brunello Clone Sangiovese is around 21 Brox. We should see Suisun Valley fruit start to harvest towards the end of September. Lodi will start to harvest more Cabernet, Zinfandel, and Merlot this week. Central Valley harvest is in full swing and will be arriving daily. Washington State Pinot Noir should start to come off the vine around 9/16, and arrive around 9/22. The Fresco Juice order deadline is 9/25 and they should start arriving the first week in October. Italian juices are set to delivery in the first week in October.

Don’t forget about our Winemaking Classes…

Hands-On Winemaking: Back by popular demand is our Winemaker Bootcamp. The September Class will start Saturday September 16th, 2023 at 9:00AM – 12:00PM (runs for 5 weeks). The October Class will start on Saturday October 21st, 2023 at 9:00AM – 12:00PM (runs for 5 weeks). Make sure to sign up via the website (link: 5 Week Winemaking Bootcamp (juicegrape.com)) or email cmusto@juicegrape.com if you are interested. There is only 1 space left in the September class and only 2 spaces left in the October class!

Winemaker In Your Pocket: Musto Wine Grape and Frank Renladi put together online courses you can access from anywhere! Check out our online classes via our sister site WinemakingInstructions.com {link: Learn How to Make Your Own Wine (winemakinginstructions.com)).

We look forward to seeing you at pick up this season! 😊

Cheers!

Christina & The Musto Crush Crew

Musto Wine Grape Co. / WinemakingInstructions.com

cmusto@juicegrape.com

Recent Comments