How to Make Syrah Wine from Chilean Wine Grapes

Chilean Syrah from Colchagua Valley has received high praise from publications like Wine Enthusiast, earning 93+pts. It’s a wine variety that is often overlooked from Chile and is a wine worth making this season. Chilean Syrah boasts flavors of plum, wild berry, and earth aromas. I highly suggest introducing this wine to oak barrels or an oak infusion. The medium acidity and powerful aromas are complemented by the French Oak flavor profile.

Yeast Suggestion: CSM yeast

Oak Suggestion: French oak barrels or chips

Wine Flavor Profile: Bold, medium tannins, blackberry, plum, wild berry, leather, smoke, chocolate, and oak

How to Make Syrah Wine from Chilean Wine Grapes:

- Crush Syrah grapes into a sanitized bin or tub. (Each 18lb crate will make 1.25 gals of finished wine).

- Apply 50ppm of Potassium Metabisulfite and stir well. Allow to sit for 8-12 hours.

- Apply .5ml of Color Pro Pectic enzyme per box diluted into a 10% solution with water to the must and stir. Allow to sit for another 8-12 hours.

- Mix Booster Rouge, FT Rouge, and Opti-Red, with spring water until it is the consistency of pancake batter and pour over top of crushed grapes. Mix in well.

- Add rehydrate CSM yeast (1g/gal) with Go Ferm rehydration nutrient and warm water. Allow to sit for 15 minutes and pour over top of crushed grapes.

- Punch down grapes 3 times per day throughout the duration of fermentation and monitor temperature and Brix levels daily. Use a hydrometer to test sugar content in a strained juice sample. Make sure the temperature does not exceed 85F.

- One day after adding the yeast, add Fermaid O, mixed with spring water into the pancake batter style slurry. Dump into grapes during a punch down.

- After the depletion of 1/3 of the Brix (when the Brix level is between 16-11), add Fermaid O that is mixed with spring water into the pancake batter style slurry. Dump into to grapes at a punch down.

- Add Malo-lactic bacteria the same day as the Fermaid K. If you are using liquid cultures, just pour over the grape must and mix. If you use the dry cultures, rehydrate them in warm spring water according to their specific directions, utilizing any rehydration nutrients recommended.

- When the Brix have dropped below zero, press the wine into a sanitized tank, carboy, or demijohn. Make sure the vessel is topped up all the way to the top of the neck and sealed properly with a bung and airlock.

- Rack after 48 hours and then again in a week. Allow MLF to complete before adding sulfites.

- Allow the wine to age and rack it every 2 months and add sulfites when racking.

- Add oak infusion after 2nd or 3rd racking. Taste test along the way until the oak profile is where you want it to be.

Interested in making your own wine? Musto Wine Grape Company is here to help! Musto’s New England’s largest supplier for home winemaking products and services. Visit juicegrape.com or give us a call at (877) 812 – 1137 to learn more.

Product Spotlight: CSM Yeast

Product Spotlight: CSM Yeast

CSM yeast was derived from Bordeaux and helps create a vibrant aromatic profile. CSM aids in adding complexity to the palate and pairs well with malolactic fermentation.

Why you want to use it:

It’s the perfect yeast for the Chilean fruit. It reduces vegetal aromas, adds complexity, stabilizes color, and helps increase the aromatic profiles of berries and spices.

Use Tips:

Fermentation starts quickly with this yeast. Be prepared to see Brix drop 24 hours after inoculation. It can stand up 14% ABV and can handle temperatures from 59–90°F. However, I highly suggest keeping your fermentation temps lower than 75°F. Once you hit 80°F you lose aromas and “burn off” flavors. Keeping your wine between 59–75°F during fermentation is a best practice.

You also want to use nutrients when using CSM; nutrients such as Fermaid-O and Fermaid-K. CSM tends to produce H2S (rotten egg smell) if there aren’t enough nutrients during fermentation.

Avoid cold shocking the yeast at inoculation. You’ll want to get the must and the yeast starter within a few degrees of each other before pitching the yeast starter. But without temperatures falling lower than 55°F. Temps below 55°F could stall fermentation and/or kill the yeast.

Goes best with:

CSM was cultivated to help ferment Cabernet Sauvignon, Cabernet Franc, Grenache, Merlot, Sangiovese, Petit Verdot. However, we have seen it used on Carmenere, Malbec, and Syrah from Chile with great results.

Dosage:

6gm/gals

Flavor Profile:

Cherry pit, raspberry, blackberry, spice, violet, bark, and sweet pepper

Ready to make wine? Musto Wine Grape Company is here to help you make the wine of your dreams! The Spring South African & Chilean winemaking season starts soon! Secure your winemaking grapes or juices and give us a call at (877) 812-1137 to speak with one of our Musto Crush Crew members. We can get you set up with everything you need and provide customer support along the way to ensure your success!

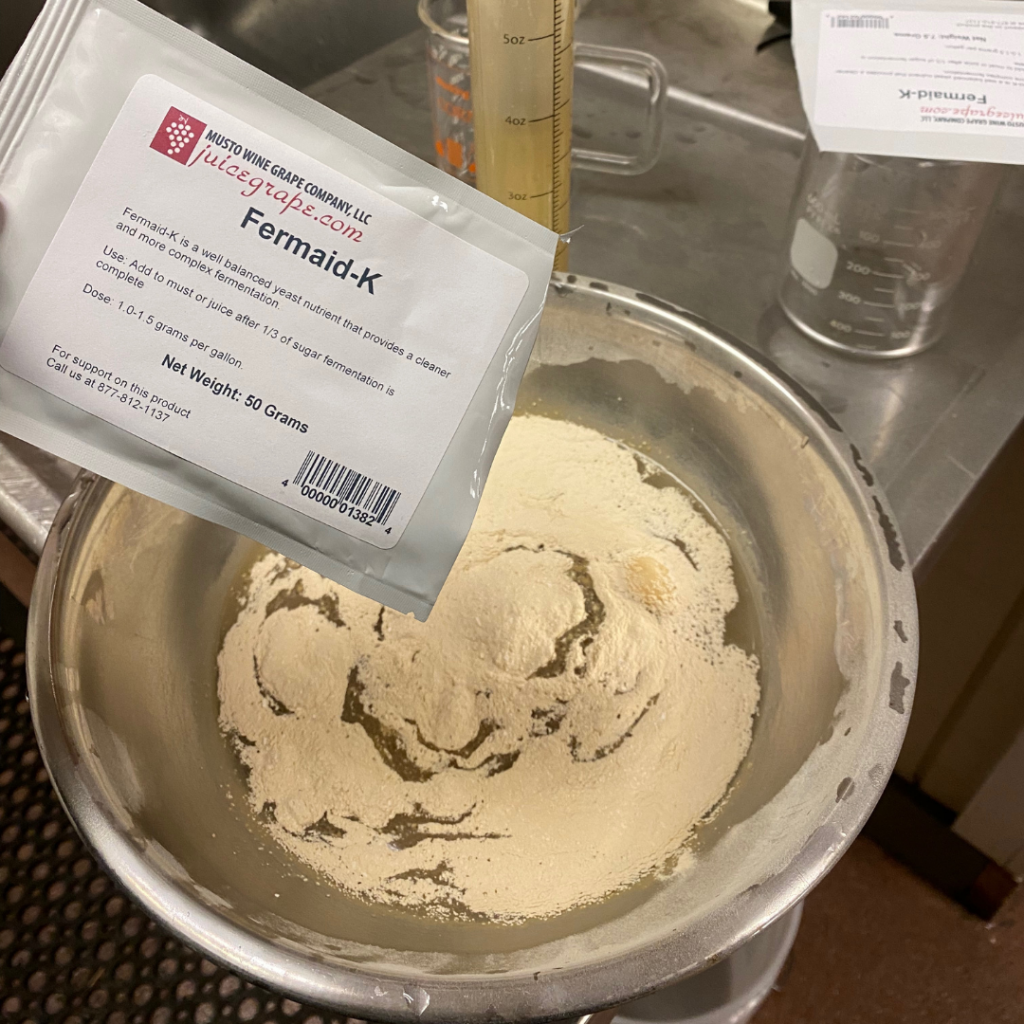

What is Fermaid K? And Why/When do we use it?

Femaid-K is a blended complex yeast nutrient that supplies ammonia salts (DAP), free amino acids (organic nitrogen derived from inactivated yeast), sterols, unsaturated fatty acids, key nutrients and inactive yeast. The unsaturated fatty acids and sterols provided by Fermaid K are important survival factors yeast cells need to maintain alcohol resistance and permease activity, and help keep volatile acidity levels low. Nitrogen is critical for protein synthesis and to maintain cellular growth. Fermaid K’s alpha amino acids provide a nitrogen source which is easier and more efficient for yeast to metabolize than nitrogen from traditional ammonia salts. The cell wall fractions in Fermaid K absorb short and medium chain fatty acids that are toxic to yeast, and provide nucleation sites to help keep the yeast in suspension.

Fermaid K is like the power bar they hand out to runners at the last mile. The power bar gives you the energy and nutrients get through those last few miles of the race.

You can add Fermaid-K at 8 Brix

The Winemaker’s Think Tank: Vol 2 – What do I need to get started making wine with fresh juice?

The Winemaker’s Think Tank?

Every Thursday we will post about a few frequently asked questions that our winemaker has answered. If you have a winemaking question you would like to have answered, please email us at support@juicegrape.com and we will try to get into next week’s post. Cheers! 🙂

What do I need to get started making wine with fresh juice?

When elevating your winemaking to the next level, often sourcing the best ingredients is the most direct path to better results. After getting great base experience using wine kits, the next logical step to wine making greatness is fresh juice. When making this change from wine kits to fresh juice, other ingredients may be needed to ensure the juice will reach its greatest potential as wine. First, evaluate your juice for acid (pH) and sugar (Brix). What are the levels present in your juice? If the Brix level is below 20, you may consider adding sugar to increase the Brix levels to 24-26. What is the pH of the wine? Juice should have a pH greater than 3.1 to ensure a successful fermentation. If the pH is higher than 3.8, consider adding tartaric acid. This will ensure a better tasting wine after fermentation as well as a more stable wine.

The next area to consider is yeast. Certain strains of yeast will amplify certain traits within the finished product of wine such as fruit character, spice notes, or floral notes. The yeast has certain parameters that it will ferment best within, so consult a winemaking expert at Musto Wine Grape to help you select the best yeast strain for your wine. The yeast is the important catalyst that will process the grape juice into wine. The yeast will need certain nutrients to best assist it with its fermentation such as a rehydration nutrient like Go Ferm, and subsequent nutrients to finish out the fermentation process such as Fermaid O and Fermaid K. Musto Wine Grape stocks yeast along with all of the aforementioned nutrients in small packages, designed for the individual buckets of juice. This will give you perfectly measured amounts of products to add to your wine, making proper fermentation simple and with no wasted/unused product.

We hope this information helps with your winemaking. If you have any follow up questions or winemaking questions in general, please email us at support@juicegrape.com.

Recent Comments