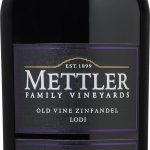

Wine Grape Spotlight: Mettler Ranch Zinfandel

Wine Grape Spotlight: Mettler Ranch Zinfandel

When making Mettler Ranch Zinfandel you can create a wine with earthy and smoky aromas. Along with a complex medley of flavors including plum, blackberry jam, tobacco, anise, and sweet oak. The sturdy but softly integrated tannins yield to subtle oak notes (if you make an oak addition) as the wine lingers on the palate. These grapes create a wine full of Zinfandel personality! Winemaker Adam Mettler suggests some light French oak to add a little extra complexity.

If you can hold off drinking your wine right away and lay it down for 1-2 years it will only gain more of that zesty, delicious personality. If you’re interested in trying out a different Zin this year, Mettler Ranch is a great choice. Email sales@juicegrape.com or call the office at 877-812-1137 for more details on how to reserve these grapes.

The Mettler Family has been farming wine grapes since the 1800’s. Recognized in the Agricultural Hall of Fame, they are 8th generation grape growers in Lodi, CA. With over 800 acres farmed in Lodi county, some vineyards being upwards of 100 years old, these vines are meticulously managed and maintained. All of their vineyards are LODI RULES certified and some are Certified Organic through the CCOF (California Certified Organic Farmers).

Lodi has a classic Mediterranean climate with warm, dry summers and cool, moist winters. The dry warm summer days allow Lodi grapes to develop full, ripe fruit flavors while the distinctive breezes maintain the natural acidity for structure and complexity in finished wines.

The Mettler Zinfandel is sourced from their vineyards by the Mokelumne River, referred to as “Old Lodi.” The soil is sandy and this sub appellation is known for being an epicenter for Old Vine Zinfandel. The vines are 50 years old, sustainably farmed, and certified through LODI RULES.

Making Mettler Ranch Zinfandel (5-6 gallons):

Ingredients:

- 2-3 cases (36lbs) of Mettler Ranch Zinfandel grapes

- 1.6 gms of Potassium Metabisulfite

- 3mL of Color Pro

- 1 – 6gal package of Go-Ferm

- 1 – 6gal package of chosen yeast (see yeast suggestions below)

- 1 – 6gal package of Fermaid K

- 1 – 6gal package of Fermaid-O

- 1 – 6gal package of Malolactic Bacteria

- Optional Additives:

- 1 – 6gal package of Tannin FT Rouge

- 1 – 6gal package of Opti-Red

- 1 – 6gal package of Booster Rouge

- .9oz of French Oak Dust

Yeast Suggestions:

Equipment:

- 1- 6 gallon carboy

- 1 – 5 gallon carboy

- 1- 50LTR fermentation pail w/lid

- 1- Crusher Destemmer or utilize Musto’s Crush/Destemm service

- 1- Press

- 2 – Airlocks

- 2- Drilled Bungs to fit Carboys (#7)

- B-Brite

- Potassium Metabisulfite

- Racking equipment

- Hydrometer

- Thermometer

- Ability to test for Total Acidity (TA), pH, and MLF

- Must punch down tool or stainless steel spoon

Winemaking Steps:

- Sanitize and Crush and Destem – Inspect your grapes. Crush and destem into clean and sanitized food grade 50LTR fermenting tub. Always allow an extra 20% of volume for fermentation purposes as the wine will “expand” throughout fermentation. Always rinse your fermentation vessel with a sanitizing strength potassium metabisulfite solution (2oz/gallon or 3tbsp/gallon). Make sure that the sanitizing solution touches all the surfaces of the fermentation vessel and that the vessel is completely emptied out of all sanitizing solution after. Shake free any drops as best you can from the fermentation vessel. Having remaining sulfite liquid in the vessel will prohibit fermentation. Do not rinse the sanitizer off with water after sanitizing as that will reintroduce bacteria to the environment.

- Once all of the grapes are crushed, try to accurately measure your quantity of must. Add ¼ tsp of potassium metabisulfite for every 5 gallons of must that you have. Mix up the must thoroughly.

- ALWAYS record the additions you make to your grape must!

- Wait for 6-8 hours after the sulfite addition and then add color pro to the must. Always mix it with water to create a 10% solution (if you use 5mls of enzyme, mix it with 45mls of water). The water allows it to better circulate throughout the must. Allow the pectic enzyme to work for 12 hours before yeast set.

- Twenty four hours after crushing the grapes, mix the container thoroughly and take and record your measurements. Measure Brix, pH, and TA. If you need to adjust your must at all, this is the time to do it. Ideally your Brix should be between 23-28 degrees, the pH between 3.4-3.7, and the TA between 6-7g/L. Your initial Brix reading, multiplied by .55, will give you a close estimate of your ending alcohol by volume percentage.

- If you would like to use fermentation tannins (FT Rouge, oak dust) or fermentation nutrients such as Opti-Red, add them after measurements and adjustments have been made. Mix any of these ingredients in thoroughly.

- After measurements have been taken and any adjustments have been made, it is time to set yeast if you are using a cultured yeast strain. Follow the yeast set directions on the packet explicitly.

- After you get to temperature and add your yeast, you may cover the vessel lightly with an old sheet or towel or place the lid gently on top of the bucket.

- Obtain a must punch tool, a long stainless steel spoon, or your bare hands, and sanitize your tool or hands with sulfite sanitizer. This is what you will use to “punch down” or mix up the must three times a day. Try to mix everything very well, pushing all of the skins back down to the bottom, getting them very wet, and bringing up the piqued from the bottom. This should be done as often as possible, preferably three times a day. [Before work (7am), after work(5pm), and before bed (10pm)] When punching down every evening, take a sample of the liquid and using your hydrometer, track the Brix depletion. You should notice a drop in Brix daily. Always record your additions to your must, your brix depletion, and punch downs.

- If you are using additional yeast nutrients to assist in fermentation you will add them after fermentation has started. Fermaid O is added at the beginning of fermentation (1 day after yeast set) and Fermaid K will be added at 1/3 depletion of the Brix (2/3 of the beginning amount of Brix). Follow the directions for the individual yeast nutrient, hydrating with water and mixing thoroughly.

- If you are adding malolactic cultures to your wine, you may also chose to do this at 1/3 Brix depletion. Follow all directions on the bacteria and nutrient packets explicitly.

- Punch down and take Brix measurements daily. When your hydrometer reads 0.90, you have fermented to dryness. At this point your malolactic fermentation may still continue, but the primary alcoholic fermentation is complete. You may now press the wine. Wash the press and sanitize using potassium metabisulfite. Again, make sure the press does not have any excessive puddles or lingering amounts of sanitizing solution remaining. Sanitize the receiving container carboy and any pumps or tubing that you may use. Anything that comes into contact with the wine should be rinsed with sulfite sanitizing solution. Place a screen (also sanitized) inside of the press to hold back any extra skins or seeds from getting through. Start scooping up the must and placing it in the press. Some of the liquid will immediately flow through, this is the “free run”. When the press is full, slowly begin pressing. Do not try and press every last drop out of the must as this can lead to seed cracking and bitterness in the wine. Fill each container to within ½” of the top and secure a bung and airlock in place. Malolactic fermentation will exude a small amount of carbon dioxide and there will be trapped gas within the wine that will need to escape the container.

- Allow the wine to sit for 2-3 weeks. You can conduct malolactic chromatography or bring a sample to a winemaker at Musto Wine Grape for analysis to ensure that your secondary fermentation is finished. At this point you should see a nice thick layer of lees in the bottom of the carboy. You will want to place the full vessel onto an elevated surface such as a table and place the new, sanitized, empty vessel on the floor below. Using a sanitized siphon, rack the wine into the new carboy. You may have space at the top which will need to be “topped off” with more wine. You can either use wine from another container, or finished wine to do this. It is very important that there is less than a 1/2” of headspace in each container. At this point you should also add 1/4tsp of potassium metabisulfite per 5 gallons of wine.

- Now it is time to let your wine age. You will need to rack it and add additional SO₂ every 3 months. Make sure you sanitize all equipment and containers when racking and keep them topped off within ½”. Come visit Musto Wine Grape for bottling advice and supplies.

For more winemaking details check out the posts below:

- Adjusting your grape must

- Racking your wine

- Post fermentation tips

- Finning agents and why they help

- Aging your wine

- Finishing your wine

Awards won by Mettler 2017 Lodi “Epicenter” Old Vine Zinfandel:

- 93 Points, Best of Class & Gold Medal – 2019 Los Angeles Wine Competition

- 91 Points – Wine Enthusiast Magazine (February 2020)

- 91 Points & Gold Medal – 2019 Sunset Int’l Wine Competition

- 91 Points – 2019 California State Fair

- Gold Medal – 2018 San Francisco International Wine Competition

If you are interested in purchasing wine grapes or winemaking juices this fall please email sales@juicegrape.com or call 877-812-1137 for pricing and information. We are looking forward to speaking with you about your 2020 vintage!

ONLINE Winemaking Classes!

Musto Wine Grape is Now Offering Online Winemaking Classes!

Musto Wine Grape and Winemaking Professor Frank Renaldi are proud to bring you WinemakingInstructions.com. Take our Winemaker Bootcamp Course or take whichever winemaking instructions classes that interest you the most. With over 45 videos to choose from there is something for everyone! Videos range in price from Free to $19.99 depending on the topic. Check out WinemakingInstructions.com today and get prepped for harvest!

Videos Available at www.WinemakingInstructions.com:

- Introduction to Winemaking

- Cleaning and Sanitizing

- Fermentation Protocol Descriptions

- Storage Vessels

- Washing and Using Used Bottles

- Wines to Blend

- Winemaker’s Bootcamp Bundle

- Corking Wine Bottles

- Degassing Wine

- Electrodes

- Sodium Hydroxide

- Testing for Pectin

- Adding Oak Powder

- Adding Yeast

- Bench Testing

- Blending Wines

- Bottles, Corks, and Foils

- Cold Soaking and Enzymes

- Handling High Brix

- Measuring and Adjusting SO2

- Oaking Your Wine

- pH and TA in Your Wine

Racking Your Wine - Stuck Fermentation

- Wine Faults

- Yeast and Nutrients

- Addressing Sulfur Issues

Back Sweetening - Bentonite

- Bottling Wine

- Filtering Wine

- Making Port

- Malolactic Fermentation

- Measuring Alcohol

- Post Fermentation Adjustments

- How to Make Rose

- Tannins

- Wine Stability

- Working with Barrels

- YAN

- Crushing and Destemming

- Making Wine from Juice

- Measuring and Adjusting Must

- Pressing

Interested in Making Your Own Wine? Give us a call (877-812-1137) or email us (sales@juicegrape.com) and we will help you get started!

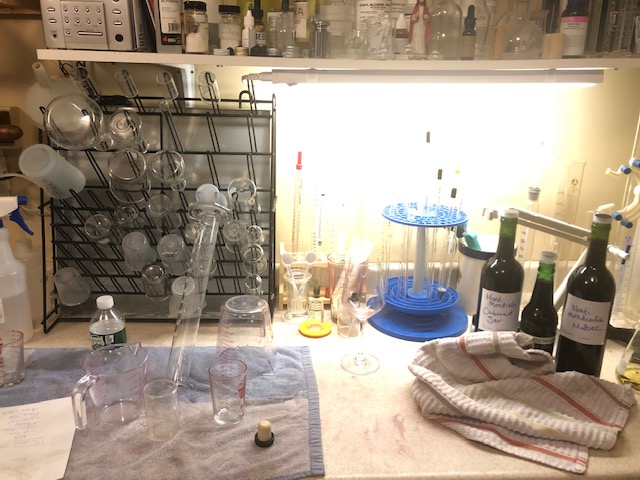

How to Set Up Your Home Winery

Setting up your home winery

There are two factors to consider when you decide to build your home winery.

- How much money are you willing to spend to buy more equipment, build rooms, or add air conditioning?

- The second factor is how much room do you have to create your winery?

I converted my entire basement into a winery. But, I did it slowly, one room at a time. Let me walk you through that and see if what I have done could apply to your place for a home winery.

I have a room which holds my variable capacity tanks and carboys. This wine is aging and waiting to be moved into barrels. This room is air conditioned due to poor cellar temperatures at my home. I also have a sink in this room for cleaning and washing. I added a five foot counter to do all my lab work. Wine racks were added to the walls above the tanks to store all my 375ml bottles of port.

The next room I built was a barrel room. I finally took the step to barrel age my reds and have never looked back. The barrel aging makes the wine so soft and complex. I have seven barrels ranging from 15 gallons to 30 gallons. I suggest you stay in this range as a home winemaker. They are easier to handle and clean. You must also remember, you will need wine on “standby” to place into the barrel once you remove the existing wine to bottle. Plan well.

My final room was needed to store all the wine moving out of the other rooms – a bottles storage room. I bought wooden wine rack kits online, and after assembly I bolted them to the walls. I then put down a floor, nice lighting and a bit of decorating to tie it all together. The most critical thing I added was air conditioning, because bottle storage needs four things – cool constant temperature, darkness, proper humidity and no vibration. All the bottles are lying horizontally and peacefully aging.

Besides proper areas to process your wine, you also need the tools to take care of this wine. Some of the “must have” tools are hydrometers, pH meters, pipettes, burrette, stir plate and an SO2 meter. These tools are needed to balance your grapes perfectly before pitching the yeast. They are also needed to adjust and protect your wine as it is aging.

Be sure to have other supplies on hand such as tartaric acid, potassium metabisulfite, fructose, tannins and oak. You will build your supplies and equipment as time goes on. Everything I talked about above will take you a level where you can become a dedicated, creative and proud winemaker!

Written by Winemaker Frank Renaldi

How much wine will my case of California grapes make?

Crates, pounds, liters, gallons, must, finished wine, juice… there’s a lot of terms and volumes floating around in your head during winemaking season. Simplify your life with the following explanation of how much volume you should expect to be getting from your grape order.

Each case of wine grapes from California and Washington State is 36lbs. Depending on the grape variety, you should yield about 2-2.5 gallons of must per case.

*Keep in mind that all of these are estimates. Some grapes will yield a bit more and some a bit less depending on the variety.*

A good rule of thumb is that 20lbs of grapes will yield roughly 1 gallon of finished wine. So each case should give you about 1.44 gallons of finished wine, equating to about 7 bottles of finished wine generally speaking..

If you want to make 5-6 gallons we suggest using 3 cases of grapes. The extra case will give you room for error when pressing and racking, plus extra wine for topping off during the aging process. If you use only 2 cases of grapes, make sure you have a 5 gallon carboy handy in case you loose a little juice during the winemaking process. You don’t want any headspace in your carboy.

For more information regarding the Fall Harvest please feel free to contact us at sales@juicegrape.com or give us a call at 877-812-1137. We are looking forward to helping you with your next great wine!

Lanza-Musto Vineyards and Suisun Valley Harvest Update {071720}

Lanza-Musto Vineyards and Suisun Valley Harvest Update

as of 07-17-20

We were able to catch up with Ron Lanza this week. He said, “Harvest in Suisun Valley is looking to be about 1 to 2 weeks earlier than last year. Bud break was 10 days earlier than last year and Mother Nature seems to be keeping up with that trend. We are already seeing color (veraison) in the Brunello Clone Sangiovese vineyards! We have been busy doing a lot of thinning this year and the crop should be the perfect size. The Malbec is looking especially good this season. We are looking forward to sending these great grapes to the East Coast!”

Grape Varieties Available:

- Barbera

- Chardonnay

- Clone 8 (“Valley Cab”) Cabernet Sauvignon

- Clone 15 Cabernet Sauvignon

- Clone 169 Cabernet Sauvignon

- Koch Cabernet Sauvignon

- Malbec

- Muscat Cannelli

- Merlot

- Mouvedre

- Petite Sirah

- Petit Verdot

- Primitivo

- Riesling

- Brunello Clone Sangiovese

- Sauvignon Blanc

- Syrah

- Tempranillo

*All grape varieties are available in 36lb cases or in frozen must by request

Juice Varieties Available:

- Chardonnay

- Napa Gamay (Pink)

- Muscat Cannelli

- Riesling

- Sauvignon Blanc

*All juice varieties are available in 5.25 gallons pails, cold settled, zero additions or balancing done to the juice.

Recent Comments