A Legacy in Every Bottle: The Alves Family Story

At Musto Wine Grape Company, we love sharing the stories behind the winemakers who turn grapes into lasting family traditions. One of those stories belongs to Justin Timpano and his father-in-law Al Alves, whose winemaking roots trace back more than 60 years to the small Portuguese village of Carvalheiro. What began with Al’s grandfather crushing grapes by hand in a stone bowl has grown into a multi-generational passion carried from Portugal to Connecticut.

Justin, tell us the story of your wife’s (Melissa’s) family and how they first got into winemaking:

My wife’s father Al and Uncle Angelo are from a small village in Portugal called Carvalheiro. It’s about an hour and a half’s drive northeast of Lisbon. It’s a beautiful area where they still own the house they grew up in, acres of farmland and hundreds of cork trees. Wine making has been a part of the Alves family for over 60 years. It started with Al and Angelo’s grandfather making wine by crushing grapes in a stone bowl by hand. Al and Angelo, along with their brother Nelson carried the tradition to states and typically made a red field blend they would bottle or keg and drink during Sporting (soccer) games and family parties. I remember the first time I saw the process at Melissa’s grandmothers house in Hartford, big blue drums, manual crusher and a homemade wood punch down. Their wine was so good and the process looked like so much fun so I asked to join them about 12 years ago and have been making wine ever since. I now make the family wine and am really proud to carry on their tradition.

Al, Angelo and I this summer at the local store in Carvalheiro having a 50 cent glass of wine

Al walking next to the family cork trees

How did you and the family both start making wine together?

I had been making wine for 5 or 6 years when Mike (my brother in law) and I went to Jonathan Edwards Winery one afternoon with our family. Mike at that point didn’t have a lot of exposure to red wine. After a few glasses of their 2017 red zinfandel, Mike was interested in joining and I wanted to do what Al, Angelo and Nelson did and make wine making a family tradition. Mike has fallen in love with the process and now hosts a podcast called Vino Volley, a show about soccer and wine. Neither of us are Portuguese but we both love Portugal and our wine is inspired by reds we have tasted from vacations and the Portuguese style field blends made by the family for generations.

How have you’ve gotten more family and friends involved over time?

I feel like every home wine maker who has friends and family that drinks and enjoys their wine somehow ends up growing their group. At one point, we had 8 or 9 guys making wine at my house until we all had kids and decided to break up the band. My good friends Kevin Lawton and Milton Quaresma now have their own setups at their houses and continue to make great wine. Kevin makes high end Cabs and Milton is on to Italian reds. We all still regularly get together and bring our favorite wines to share. I think and hope wine will keep us connected as our kids grow. This year we are expanding our team again with my Dad, Jim, making a rosé and cousins Danny and Bruno joining in on our red blend.

Below are pictures of Kevin and his family making thier high end cabernet at home!

For Justin and Al, winemaking is more than a hobby—it’s a thread that connects generations, cultures, and memories. From a small stone bowl in Portugal to a family cellar in Connecticut, every crush, every bottle, and every shared glass is a tribute to the love, laughter, and legacy that started it all. It’s stories like theirs that remind us why we do what we do at Musto Wine Grape Company—because behind every great wine is a family, a friendship, and a tradition worth preserving.

🍷 Want to start your own winemaking story?

Musto Wine Grape Company is here to help you every step of the way, from grapes and juices to equipment, education, and support. Visit www.juicegrape.com or stop by to get started.

The Guerriero Family Legacy: From Grapes to Glass

Tell us about your winery/winemaking/vineyard history and/or story

For over six decades, the Guerriero Family has been packing and shipping premium

California juice grapes. Our family started packing and shipping juice grapes in the Lodi region of the San Joaquin Valley in 1953 and eventually expanded to the Central Valley. This legacy began with Tony Guerriero, who turned a Bronx produce truck into a cross-country wholesale operation—and it continues today with third and fourth generation family members, Joe and his sons Joey and Tony Guerriero, and his grandchildren Dominic and Giovanna Guerriero. Many of our distributors today are the children or grandchildren of buyers our father and grandfather once served. This is not just business—it’s generational trust. In 2018, Cry Baby Wine was founded as a tribute to a dream that spanned three generations. Joe Guerriero brought to life what his grandfather and father had long envisioned: a locally hand-crafted, family-owned winery offering award-winning wines for every palate.

Across the U.S. and Canada, customers look for “the baby who is crying”—our Cry Baby label. It has become our signature, known for quality, flavor, and family pride. Many home winemakers swear by our grapes and wines, and that loyalty is earned with every bottle. Our experience in juice grapes runs deep. From pruning to harvest, we partner with some of California’s most respected farmers to ensure premium grape quality. We personally supervise vineyard selection and care, harvest timing, packing and shipping, and cold chain management. Our grapes are picked at peak maturity, forced air cooled to 32°F and shipped with the utmost care to preserve freshness and integrity.

What excites you about working with Barbera D’Asti in the Central Valley, and how does this region’s climate and terroir influence the grape compared to its traditional Italian roots?

What excites us about working with Barbera in the Lodi region of the San Joaquin Valley is how beautifully it bridges old-world character with new-world energy. In its native Asti, Barbera is prized for its high acidity, red-cherry brightness, and food-friendly elegance. Here in the Lodi region of the San Joaquin Valley, our warm days and fertile soils give the grape a riper profile—lush blackberry and plum alongside that signature tangy cherry core—while the natural acidity keeps everything lively and balanced. The result is a Barbera that’s both approachable and expressive, carrying a sense of place while honoring its Italian heritage. That contrast and harmony are what make it such a rewarding grape to work with.

What flavor profiles and structural elements (acidity, fruit notes, tannins) stand out most in Central Valley Barbera D’Asti?

San Joaquin Valley Barbera d’Asti–styled wines showcase ripe red and black fruit, lively acidity, smooth tannins, and a juicy, food-friendly structure, a California-sun expression of a naturally bright and approachable grape.

Are there qualities that make Barbera D’Asti especially approachable—or tricky—for home winemakers and smaller wineries?

Barbera is actually one of the most approachable grapes for smaller wineries and even home winemakers because of its naturally high acidity, juicy fruit, and soft tannins. It doesn’t require aggressive tannin management or years of barrel age to taste balanced—it can be bright, smooth, and food-friendly fairly early on. The tricky part is that the same acidity that makes it refreshing can feel sharp if the grapes aren’t fully ripe, and its lighter skin means you need to be thoughtful about color and oak use. But with a little care, Barbera rewards you with wines that are both expressive and inviting.

What techniques or approaches do you recommend to bring out the best in Barbera from the Central Valley? (e.g., managing acidity, oak vs. stainless, blending choices)

To bring out the best in San Joaquin Valley Barbera, we focus first on balance in the vineyard, picking when acidity is right, but fruit has developed full flavor. In the cellar, stainless steel fermentation keeps the fresh cherry and raspberry notes alive, while a touch of neutral or lightly toasted oak can add roundness without overwhelming its natural brightness. We also keep maceration gentle to avoid harsh tannins, since Barbera’s strength is its acidity and fruit, not heavy structure. Some producers blend in a small number of darker varietals like Syrah or Petite Sirah to boost color and body, but even on its own, Barbera really shines when you let its lively character lead the way.

Are there any misconceptions or common mistakes you see when people work with Barbera D’Asti that you’d like to clear up?

One common mistake with Barbera is treating it like a high-tannin grape. Winemakers sometimes over-extract, trying to pull out more structure, but that just makes it rough. Another is leaning too heavily on new oak, which can bury the fruit and throw the acidity off balance. And perhaps the biggest misconception is thinking its high acidity is a flaw—it’s actually Barbera’s greatest strength, the reason it’s so vibrant and food-friendly. In the San Joaquin Valley, that balance of ripe California fruit with naturally bright acidity is exactly what makes Barbera so rewarding when handled with a light touch.

If you’re looking for a wine that offers the best of both worlds—old-world elegance with a California twist—Barbera d’Asti is it. With its vibrant fruit, smooth texture, and food-friendly acidity, it’s a grape that feels right at home on the dinner table or shared among friends. Whether you’re a seasoned winemaker searching for a reliable varietal to craft, or simply a wine lover ready to explore something new, Barbera d’Asti delivers balance, character, and a taste of tradition with every sip. Don’t miss the chance to bring a little Italian heritage and California sunshine into your glass—Barbera is waiting for you. Call 860-278-7703 or email sales@juicegrape.com

Take the Guesswork Out of Harvest—We’ll Handle the Details

Did you know we offer complimentary, custom fermentation protocol creation for winemakers and wineries?

Tell us what you’re making—and we’ll map out your entire fermentation process down to the gram.

✅ Yeast + Nutrients

✅ Additions + Timing

✅ Step-by-step instructions tailored to your varietals, style, and winemaking goals

Why Pre-Order Your Protocol?

✔️ Save time during harvest — no scrambling at the cash register

✔️ Cut down on back-and-forth calls — everything ready and waiting

✔️ Streamline your season with a dialed-in plan built just for you

📞 Let’s get you set up early. Call us at 877-812-1137 or email sales@juicegrape.com to pre-order your fermentation protocol and supplies.

One quick call now = smoother harvest later. Let’s make this your most organized vintage yet!

Cheers,

The Musto Wine Grape Co. Team

Wine Spotlight: Bold Elegance – South African Shiraz Unveiled

Interested in making South African Shiraz? Give us a call at 877-812-1137 to speak to a winemaking representative about your order.

Appearance:

In the glass, South African Shiraz commands attention with its deep, inky purple color. The richness of its hue hints at the robust character that awaits.

Aroma:

Upon the first swirl, the nose is greeted by an enticing bouquet of dark fruits and subtle spices. Blackberry and ripe plum take center stage, accompanied by a hint of black pepper and a touch of smoky oak (either French or American oak, medium toast). The aromatic profile is bold and inviting, setting the stage for the complex layers to unfold. (yeast suggestions: BDX, D80, D254)

Palate:

As the wine graces the palate, it delivers a symphony of flavors that reflect the warmth and intensity of the South African sun. Black cherry and blueberry dance alongside notes of dark chocolate and a subtle hint of vanilla from careful oak aging (either French or American oak, medium toast). The wine’s full-bodied nature is complemented by velvety tannins that add a luxurious texture, creating a well-balanced and deeply satisfying experience.

Flavor Profile:

South African Shiraz is a showcase of the varietal’s bold and expressive character. The dark fruit flavors are complemented by a savory undercurrent, with a touch of black pepper adding a hint of spice. The integration of oak is seamless, contributing to the wine’s complexity without overpowering its vibrant fruit profile.

Pairing Suggestions:

A robust Shiraz is a natural companion to hearty dishes. Pair it with a juicy grilled steak, lamb stew, or a rich, meaty pasta for a perfect match. Its bold flavors and well-structured tannins also make it an excellent candidate for aging, allowing the wine to evolve and develop further complexity over time.

Overall:

South African Shiraz is a testament to the region’s ability to produce wines of depth and character. It balances power with finesse, showcasing the winemaker’s artistry in capturing the essence of the grape and the terroir. It’s a wine that invites contemplation and celebration.

Interested in making South African Shiraz? Give us a call at 877-812-1137 to speak to a winemaking representative about your order. Cheers!

Product Spotlight: Crusher Destemmer

You’ve got your fresh wine grapes in tow, and now its time to make some wine! If you don’t take advantage of our crush and destem service, you’ll have to crush and destem your grapes. We offer a variety of crushers, and crusher-destemmers to fit any winemaking project. We’ll cover some of our top options to help you determine which one suits you best! The most popular crusher destemmer is the stainless steel electric crusher destemmer. With an electric motor that does all the elbow work featuring an all stainless steel assembly, it is corrosion resistant and will last you for many winemaking seasons to come.

Stainless Steel Electric Crusher Destemmer

This crusher destemmer is motorized, with a stainless steel hopper and body. It has an hourly production rate of 1,500kg (about 3,330lbs). Its electric motor is 100volts/1hp, and it’s dimensions are 100 x 550 x 580h mm. The hopper dimensions are 900 x 460 mm and it has a removable protection box. This piece of equipment is a great investment for a winemaker who has plans to crush and destem an average of 50 or more lugs of grapes. With proper cleaning and storage, this machine will last a winemaking lifetime! We also carry the matching stand for our crusher destemmers, in both painted and stainless steel.

If the stainless steel crusher destemmer is a bit out of your winemaking budget, we carry one nearly identical but that is painted:

Electric Crusher Destemmer with Painted Hopper and Body

All the specs are identical to the stainless steel crusher destemmer except for the fact that this one is painted steel. The downfall of this machine is that it is susceptible to corrosion if not cleaned and stored properly. With proper cleaning and storage, it will surely last you many years. If you’re looking for something in the middle, we have that too!

Electric Crusher Destemmer with Stainless Steel Hopper and Painted Body

If you’re looking for a slightly more budget-friendly crusher destemmer with that boost of corrosion protection, this stainless steel hopper, painted body crusher destemmer is perfect. Once again you’ve got identical specs to our other options above, without having to compromise too much on either advantage of corrosion protection or budget.

If you are a home winemaker with less than 50 lugs of grapes on average and a smaller equipment budget, we also carry manual grape crushers and crusher destemmers. They come in the same options as our electric crusher destemmers including fully stainless steel, fully painted, or stainless steel hopper/painted body.

Stainless Steel Manual Crusher Destemmer

The Grifo hand powered crusher destemmer has a hopper size of 900 x 500 mm, and the Aluminum rollers are 220 mm. The hourly production rate is about 700-800kg (1500-1750lbs) and is a great option for a winemaker processing up to about 50 lugs of grapes and is looking for corrosion protection.

Painted and Stainless/Painted Manual Crusher Destemmer

With the same specs as the stainless steel but more wallet friendly, the painted and stainless manual crusher destemmer is a great option.

With lots of options to choose from, Musto Wine Grape has your winemaking needs taken care of.

Interested in making your own wine? Musto Wine Grape Company is here to help! Musto’s New England’s largest supplier for home winemaking products and services. Visit juicegrape.com or give us a call at (877) 812 – 1137 to learn more.

How to Make Syrah Wine from Chilean Wine Grapes

Chilean Syrah from Colchagua Valley has received high praise from publications like Wine Enthusiast, earning 93+pts. It’s a wine variety that is often overlooked from Chile and is a wine worth making this season. Chilean Syrah boasts flavors of plum, wild berry, and earth aromas. I highly suggest introducing this wine to oak barrels or an oak infusion. The medium acidity and powerful aromas are complemented by the French Oak flavor profile.

Yeast Suggestion: CSM yeast

Oak Suggestion: French oak barrels or chips

Wine Flavor Profile: Bold, medium tannins, blackberry, plum, wild berry, leather, smoke, chocolate, and oak

How to Make Syrah Wine from Chilean Wine Grapes:

- Crush Syrah grapes into a sanitized bin or tub. (Each 18lb crate will make 1.25 gals of finished wine).

- Apply 50ppm of Potassium Metabisulfite and stir well. Allow to sit for 8-12 hours.

- Apply .5ml of Color Pro Pectic enzyme per box diluted into a 10% solution with water to the must and stir. Allow to sit for another 8-12 hours.

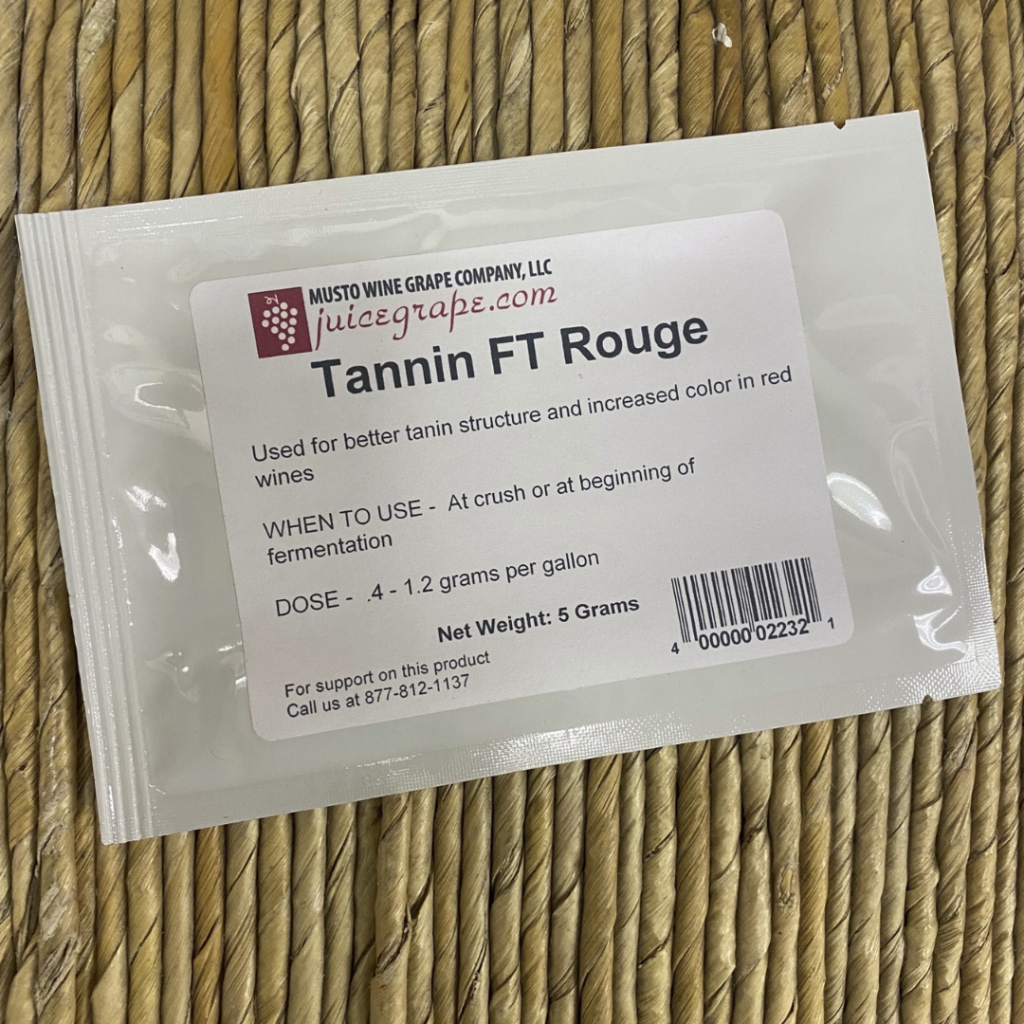

- Mix Booster Rouge, FT Rouge, and Opti-Red, with spring water until it is the consistency of pancake batter and pour over top of crushed grapes. Mix in well.

- Add rehydrate CSM yeast (1g/gal) with Go Ferm rehydration nutrient and warm water. Allow to sit for 15 minutes and pour over top of crushed grapes.

- Punch down grapes 3 times per day throughout the duration of fermentation and monitor temperature and Brix levels daily. Use a hydrometer to test sugar content in a strained juice sample. Make sure the temperature does not exceed 85F.

- One day after adding the yeast, add Fermaid O, mixed with spring water into the pancake batter style slurry. Dump into grapes during a punch down.

- After the depletion of 1/3 of the Brix (when the Brix level is between 16-11), add Fermaid O that is mixed with spring water into the pancake batter style slurry. Dump into to grapes at a punch down.

- Add Malo-lactic bacteria the same day as the Fermaid K. If you are using liquid cultures, just pour over the grape must and mix. If you use the dry cultures, rehydrate them in warm spring water according to their specific directions, utilizing any rehydration nutrients recommended.

- When the Brix have dropped below zero, press the wine into a sanitized tank, carboy, or demijohn. Make sure the vessel is topped up all the way to the top of the neck and sealed properly with a bung and airlock.

- Rack after 48 hours and then again in a week. Allow MLF to complete before adding sulfites.

- Allow the wine to age and rack it every 2 months and add sulfites when racking.

- Add oak infusion after 2nd or 3rd racking. Taste test along the way until the oak profile is where you want it to be.

Interested in making your own wine? Musto Wine Grape Company is here to help! Musto’s New England’s largest supplier for home winemaking products and services. Visit juicegrape.com or give us a call at (877) 812 – 1137 to learn more.

Product Spotlight: CSM Yeast

Product Spotlight: CSM Yeast

CSM yeast was derived from Bordeaux and helps create a vibrant aromatic profile. CSM aids in adding complexity to the palate and pairs well with malolactic fermentation.

Why you want to use it:

It’s the perfect yeast for the Chilean fruit. It reduces vegetal aromas, adds complexity, stabilizes color, and helps increase the aromatic profiles of berries and spices.

Use Tips:

Fermentation starts quickly with this yeast. Be prepared to see Brix drop 24 hours after inoculation. It can stand up 14% ABV and can handle temperatures from 59–90°F. However, I highly suggest keeping your fermentation temps lower than 75°F. Once you hit 80°F you lose aromas and “burn off” flavors. Keeping your wine between 59–75°F during fermentation is a best practice.

You also want to use nutrients when using CSM; nutrients such as Fermaid-O and Fermaid-K. CSM tends to produce H2S (rotten egg smell) if there aren’t enough nutrients during fermentation.

Avoid cold shocking the yeast at inoculation. You’ll want to get the must and the yeast starter within a few degrees of each other before pitching the yeast starter. But without temperatures falling lower than 55°F. Temps below 55°F could stall fermentation and/or kill the yeast.

Goes best with:

CSM was cultivated to help ferment Cabernet Sauvignon, Cabernet Franc, Grenache, Merlot, Sangiovese, Petit Verdot. However, we have seen it used on Carmenere, Malbec, and Syrah from Chile with great results.

Dosage:

6gm/gals

Flavor Profile:

Cherry pit, raspberry, blackberry, spice, violet, bark, and sweet pepper

Ready to make wine? Musto Wine Grape Company is here to help you make the wine of your dreams! The Spring South African & Chilean winemaking season starts soon! Secure your winemaking grapes or juices and give us a call at (877) 812-1137 to speak with one of our Musto Crush Crew members. We can get you set up with everything you need and provide customer support along the way to ensure your success!

SOS: Sluggish/stuck fermentation

Many a winemaker has lamented the dreaded stuck fermentation. With so much to deal with during harvest time, the last thing you should be worried about is a ferment that has just up and quit. But sometimes it happens – knowing what to do when it does will be a life saver during an otherwise potentially unfortunate moment in a wine’s life. We’re here to walk you through how to handle this, what to do, and most importantly, how to do it.

Step 1: Think about why it may have gotten stuck

This is going to help you moving forward, both with this wine and with future ferments. Was there too much sugar in the juice or must to begin with? Was the fermentation temperature too cool or too hot? Did you choose a yeast that doesn’t do well with high sugar levels? Were nutrient levels too low?

Considerations before restarting

- Adding lysozyme can halt spoilage organisms which are often present in sluggish or stuck fermentations

- Resuke can lower toxin levels that have accumulated which will give you a better chance for a healthy restart. If you add this you will rack off of it 1-2 days later.

- Incorporate Go-Ferm and Go-Ferm Protect Evolution to ensure health of ensuing restarting fermentation

- Carefully choose what yeast you will re-pitch with. 43, 43 Restart, Fermivin Champion, K1 (V1116), Vin 13, BC, and DV10 are great choices.

Step 2. Add a complex yeast nutrient

This is going directly into the stuck wine tank. If you think you may have a spoilage bacteria problem, this is the time you would be adding lysozyme.

Step 3. Combine equal parts stuck wine and water in another vessel

This is known as the “mother restart tank.” At this moment it will be totaling 2% of whole volume.

Step 4. Rehydrate yeast nutrient + yeast as you would when pitching yeast the first time

This is the exact same process you did during the initial yeast pitch.

Step 5. Add the yeast to the mother restart tank

As always, there should be a <18F difference between the yeast mixture and the mother restart tank liquid temperature.

Step 6. Add 10% of the stuck wine to the starter culture

Wait 20-30 minutes.

Step 7. Add 20% of the stuck wine to the starter culture

Wait 20-30 minutes.

Step 8. Repeat until the remainder of the stuck wine has been added to the mother restart tank

Don’t skimp on waiting the 20-30 minutes at each of the following steps. Give it time to acclimate!

Temperanillo: A Spanish Grape Fit for a Queen

Temperanillo is an incredibly fruity and juicy varietal of wine grape that dates back over 2000 years in Spain. It is the most widely planted varietal in Spain, and the third most widely planted in the entire world (as of 2015). It is one of the oldest genetically traceable grapes in Spain and has been called the Noble Grape of Spain. Its grapes were often used in wine production for the noble class of the country, as well as for religious purposes. The conquistadores brought the grape to South America in their travels, further popularizing the varietal. While the name Temperanillo may sound unfamiliar to some winemakers, it is the primary grape in Rioja blends, a name often more popular to the consumer.

Temperanillo is famous for its direct and lush strawberry flavors. It has a bit higher level of acidity, really bringing out the bright strawberry and plum flavors. The grape has a thicker blue-black skin with a colorless interior. Limited skin contact at crush can generate a nice rosé, embracing the acidity and berry flavors of the wine. Prolonged skin contact throughout fermentation will generate the traditional, full bodied red. Temperanillo can stand as a full-bodied, fruity red on its own or can work well with other varietals in blends. To create a traditional Rioja blend, Temperanillo should be the largest percentage of the blend, coupled with varietals such as Grenache, Carignane, Merlot, or Cabernet Sauvignon. The wines can either be blended at crush or post fermentation, the latter giving the winemaker more finite control over the blend. Using yeast strains CLOS or VRB, which are isolated from ancient Spanish wineries, will help to enhance the overall structure and mouthfeel of the wine, helping the winemaker to recreate a traditional Rioja blend. The VRB yeast specifically, will also help to promote those lush fruit forward characteristics that the varietal is known for. The use of Opti-Red and Booster Rouge as supplemental yeast nutrients will help to secure color and tannic structure. Oak may be supplemented at fermentation to help preserve the grape tannins and then also added later to add flavor during the wines’ maturation process. We always advise to use a complete nutrition program throughout fermentation, including the use of Go-Ferm, Fermaid O, and Fermaid K. This will help avoid any stuck fermentations and off aromas. Temperanillo, as most reds, will benefit from malolactic fermentation.

Temperanillo is a versatile, early ripening varietal with a long history of contributing to great wines. From its origin in Spain, to its travels and proliferation in the New World, its fruity legacy has carried on creating wines fit for royalty or for adventurous winemakers, like us.

Check out these Videos of our Tempranillo being Crushed & Pressed!

IMG_2640_Tempranillo Crush_Musto Wine Grape_Winemaking

IMG_2641_Tempranillo Press_Musto Wine Grape_Winemaking

by the Winemakers at Musto Wine Grape

Recent Comments